Atomic hydrogen partly diffuses into materials during production and operation. If this results in degradation of the material properties, the term hydrogen embrittlement is used. The Fraunhofer IWM has set itself the task of better understanding and mastering such chemical processes and their consequences. For this purpose, a new laboratory for material qualification for hydrogen applications has now been set up.

Hydrogen links the various sectors of energy use – heat, electricity, industry and transport – and is therefore an important component of the energy system transformation process. Hydrogen is an important starting product for many chemical products, for example for ammonia production using the Haber-Bosch process. However, hydrogen embrittlement, for example, impedes the use of high-strength steels for lightweight construction in mechanical engineering, as these materials in particular are often severely affected. The Fraunhofer IWM has therefore set itself the goal of investigating the influence of hydrogen on materials and products more closely.

The institute is involved in three ongoing public funding projects aimed at qualifying materials for use in gaseous hydrogen. The funding is part of Hypos, a research programme funded by the German Federal Ministry of Education and Research (BMBF) through Initiative 2020. Based on the measurement results, design specifications and service life predictions are made.

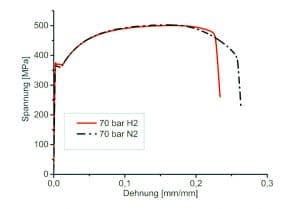

The first project, Hypos-PIMS (Pipeline Integrity Management System), aims to develop a model to evaluate the service life and integrity of long-distance pipelines for the transport of hydrogen-containing gases. The project also includes the qualification of new materials and existing materials, for example by SSRT and crack growth tests.

The second project, Hypos-UGS (underground storage), deals with the storage of hydrogen gas in large underground salt caverns. The potential storage quantities correspond to a supply of energy to Germany for several weeks. The Fraunhofer IWM uses mechanical tests and the model-based description of the static and cyclic breaking loads to qualify the steels and weld seams used in the risers for the injection and withdrawal of hydrogen.

…

read more in H2-international July 2019

Author:

Dr. Ken Wackermann, Fraunhofer Institut für Werkstoffmechanik IWM, Freiburg

0 Comments