Renewably sourced hydrogen is an essential energy carrier for achieving COP21 climate targets. The gas can store and deliver energy anywhere, anytime, meeting demand regardless of generation facilities and end users.

However, a reliable and safe infrastructure, including pipelines and control systems, is needed to ensure that a storage medium such as hydrogen can really play to its strengths and guarantee supply. This spawned the idea of using the national pipeline system, as well as its underground storage facilities, to transport, distribute and store hydrogen blends and use, or, more specifically, convert sections of the network to deliver pure hydrogen. The challenging part is how to safely handle a gas that has very special physical properties. H2-PIMS, a project supported by the HYPOS initiative, is currently tackling this issue. It has created a rating system, PIMS, for pipelines transporting hydrogen blends. PIMS stands for Pipeline Integrity Management System, and is used to investigate, on behalf of the pipeline operator, whether the current gas infrastructure meets the safety and material standards required to deliver blends. The PIMS safety and suitability assessment will form the basis for suggestions on how to run an economically and technically viable system, what needs refurbishing and where to build new pipelines.

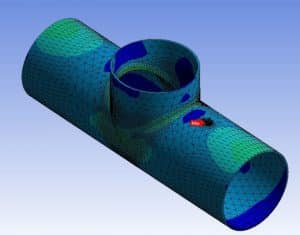

PIMS is based on pipeline specifications, some of which fluctuate while the network is in operation. The reasons for this are manifold, ranging from erosion and insulation issues to outside intervention, previously unknown material defects (e.g., in the weld seam) and transient process parameters.

The basics

Current discussions center around how to use network specifications, process parameters and pipe measurements (e.g., diameter and wall thickness, material and grade, surface quality, test results, and time in operation) to reveal the layout needed to convert pipelines. There are strong arguments for taking a staunchly conservative approach to first assessments of network stability to reduce stresses on pipe walls and provide a rough estimate of hydrogen-induced damage under steady-state operating conditions. To this end, one could use the tensile strengths mentioned in EIGA’s IGC DOC 121/14 guidelines. Other quality and design issues for constructing or converting pipelines that deliver hydrogen can be found in ASME standard B31.12-2019.

Pipeline operators could also lower pipe pressure until the required threshold values are met. If that does not help either, they can turn to PIMS, supported by the German education and science ministry. This will expand the list of methods at their disposal by including tools designed for analyzing hydrogen blends. PIMS offers suitable, descriptive models and verified analytical and predictive algorithms that provide operators with highly granular analyses of network conditions and illustrate quality changes over time.

…

read more in H2-international August 2020

Authors:

Dr. Holger Brauer, Mannesmann Line Pipe GmbH, Siegen, Germany

Marco Henel, DBI Gas- und Umwelttechnik GmbH, Leipzig, Germany

Albert Großmann, Dr.-Ing. Veenker Ingenieurgesellschaft mbH, Leipzig, Germany

I read your article carefully, it helped me a lot, I hope to see more related articles in the future. thanks for sharing.