No energy transition without hydrogen. H2 is a central energy storage medium in a world liberated by fossil energies, and its use is the key to decarbonizing industrial processes. At the Hydrogen + Fuel Cells Europe 2025 from March 31 to April 4, which takes place at the Hannover Messe, visitors can learn which solutions and technologies the hydrogen industry can already offer today. Over 500 exhibitors from all areas of hydrogen use are presenting their services and products ⎼ from start-up to large, internationally known companies, to renowned research institutes.

This year, organizer Tobias Renz again is offering visitors two forum areas: At the Technical Forum, the exhibitors will have the opportunity to present their latest developments and products in short lectures. This also includes an “elevator pitch” on the subject of hydrogen production. At the Public Forum, exhibitors and guests from industry and politics will discuss new projects and developments. Here the production of green hydrogen and its derivatives from renewable energies, CO2-neutral industrial production and fuel cell applications are in focus.

H2-international, in this trade fair preview, is focusing on a selection of innovations that visitors expect this year.

Hydrogen transport

Hydac is showing a new sensor-based clamping tape for hydrogen tanks in Hannover. The “Hy-Ros H2 Mount Smart” is said to be the world's first sensor-based transport protection for this application. The clamping tape equipped with sensors is intended to improve the safety of H2 vehicles, because it enables reliable real-time monitoring of the tank attachment. The circumference of H2 tanks can change by up to 2.5 percent in the refueling and emptying process, which is a challenge for the fastening systems.

Hydac compares its preventive approach to a tire pressure monitoring system. The data about the condition and integrity of the fastening is continuously supplied, which means that any deviations can be recognized early and appropriate measures can be initiated.

Hydac, Hall 13, Stand C44

Components for fuel cells and electrolysis systems

The Swiss company Celeroton TurboCell has specialized in the development and production of ultra -high turbo compressors and drive systems for fuel cell applications. The products are used in applications such as intralogistics, the heavy-duty area, in stationary systems, drones and the marine sector. The company has expanded its portfolio of next-generation compressors and wants to increase the number of quantities. The complete solutions consist of the gas-stored turbomachine with an electric motor as a construction unit and coordinated electronics.

New is the CTI-1100 compressor, the second generation of the turbo compressor with integrated inverter of the company. The new generation should have a higher efficiency and improved aerodynamics and at the same time offer a compact size. Thanks to the efficiency and a long lifespan of the compressor system, customers should be able to achieve low total operating costs.

Likewise new is the CTE-4000 compressor with CC-4000-inverter, which is intended for the air supply of fuel cells with a net output of 100 to 200 kW. The new system is available with an optional turbine expander and in several aerodynamic modes. In addition to a portfolio made of standard systems, Celeroton TurboCell also offers tailor-made solutions for specific customer requirements.

Fig. 2: The compressor CTE-4000 ensures the air supply of fuel cells, Source: Celeroton TurboCell

Celeroton TurboCell, Hall 13, Stand D50

The automation company Pilz presents solutions for functional safety in the hydrogen industry. It is about recognizing gas leaks reliably and quickly, always keeping pressure, level, voltage and electricity in view and safely monitoring combustion processes. Proven security principles of automation are used. Pilz also shows how hydrogen applications can be protected against manipulation and incorrect operation.

Safe automation is also a topic on the accompanying lecture program of the trade fair: At the Public Forum, Albert Cot, Market Development Engineer at Pilz, is reporting on the challenges of "functional security" and "industrial security" in hydrogen applications. At the Technical Forum, Thomas Braasch, Sales Engineer at Pilz, is dealing with the importance of functional security and industrial security in electrolysis procedures.

Pilz, Hall 13, Stand D34

Neo Hydrogen Sensors, part of the Neooxid Group, offers H2 measurement technology and burners. At this year's Hannover Messe, the company is presenting a new generation of intelligent hydrogen sensors. According to the company, conventional H2 gas sensors often reach their limits when highest demands on concentration resolution and the resistance to pressure, temperature and moisture are required. Such requirements prevail, for example, in the automotive industry or aerospace technology. The sensors of Neo Hydrogen Sensors GmbH should meet exactly these challenges and enable precise H₂ measurement, even under the most extreme conditions.

In addition, the company presents catalytic hydrogen burners for an emissions-free combustion. These include catalytic convertors for the efficient cleaning of electrolysis gases. The company has maintained a branch in Canada since 2021 and can therefore also serve the innovative market of this year's partner country of the Hannover Messe.

Neo Hydrogen Sensors, Hall 13, Stand E19/3 (NRW Pavilion)

The engineering office Emcel specializes in advice and engineering in the field of hydrogen, fuel cells and e-mobility. For customers, the engineers develop concepts for the energy transition and sector coupling and support in the development of products. This can be vehicles, hydrogen refueling stations or electrolyzers.

The team led by managing director Marcel Coneille also offers its customers the measurement of the hydrogen purity and quality. The company's H2 quality system enables continuous real-time monitoring of the hydrogen quality on site and at all points in the value chain. Fair visitors can experience live how the measuring device detects different contaminants. Because at the stand, the company wants to demonstrate how reliably and easily the measurement technology can be to ensure the hydrogen purity today.

Fig. 4: The engineering office EMCEL presents a measuring device for hydrogen purity, Source: Emcel

Emcel, Hall 13, Stand E15

Heraeus Precious Metals, a provider of precious metals, is coming to the exhibition center with the new Actydon brand. The new product family belongs to “Actydon | Platin". These are platinum catalysts, the area of application of which is primarily electrodes of PEM electrolyzers and PEM fuel cells, which are also used in other fuel cell and electrolysis technologies. "Actydon | Iridium ”includes the corresponding iridium solutions. Among them are innovative catalyst solutions with low iridium content and catalysts that combine iridium with ruthenium.

Heraeus Precious Metals also offers a precious metal recycling for hydrogen applications, and also recycling entire stacks. The company recycles old materials as well as production residues and production waste, such as paints and pastes from the fuel cell and electrolyzer area with high precious metal return rates. "Actydon | Loop ”depicts the recycling family of the company's product portfolio. The recycled precious metal can be used for the next generation of applications in the hydrogen economy.

Fig. 5: Under the Actydon brand, Heraeus sells precious metal catalysts for hydrogen applications, Source: Heraeus

Heraeus Precious Metals, Hall 13, Stand C21

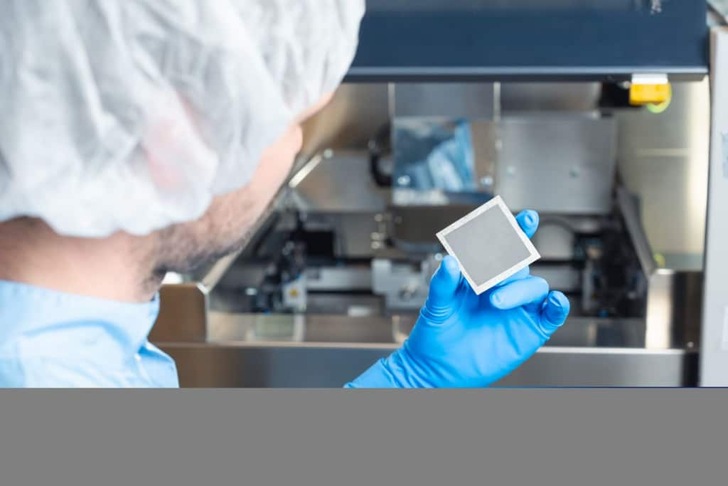

Research

In order to reduce the material and manufacturing costs for PEM electrolyzers, the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) is researching scalable production processes for catalyst-coated membranes (CCM). At this year's Hannover Messe, the Institute is presenting microporative transport layers (MPLs), which the researchers have made scalable for the first time using industrial screen printing systems. The approximately 20-µm fine MPLs should enable the use of catalyst layers with significantly reduced iridium loading by improving the connection to the catalyst and thus increasing its use. In addition, they should simplify the use of thinner membranes so that ohmic losses can be reduced.

The institute also examines customer-specific procedures for the production of membrane electrode assemblies (MEAs) for electrolyzers and fuel cells. Various MEA designs with a reduced precious metal load can be seen at the exhibition stand, manufactured with commercially available materials.

In addition, Fraunhofer ISE is showing the 3D exhibit " Wasserstoff-Modellregion" (hydrogen model region) as a typical local, self-contained hydrogen infrastructure with regional production, distribution and storage, but also with connection points to national and international infrastructures. The exhibit is intended to represent the competencies of Fraunhofer ISE over the entire hydrogen value chain.

Fig. 6: Fraunhofer ISE has produced a microporous titanium layer on a titanium fiber substrate with the screen printing process, which is supposed to serve as an MPL, Source: Fraunhofer ISE / Joscha Feuerstein

Fraunhofer ISE, Hall 13, Stand C41

The institute for technical thermodynamics of the German aerospace agency (DLR) also deals with catalysts for electrolysis and fuel cells. The researchers use flame spray pyrolysis. According to the institute, this technology needs little resources to produce materials quickly and in large quantities. It does not change the heat or the chemical composition if it is used on a larger scale. With this technique, the DLR has developed stable catalysts for PEM fuel cells and electrolyzers. These should show an extraordinary performance and durability. And that with reduced amounts of precious metal catalysts.

In addition, the researchers are working on the use of pressure hydrogen for heat pumps or air conditioning systems. A heat exchange reactor is operated with different metal hydride powders, which also produces heat and cold. The heat and cold can then be used, for example, in trains, trucks, buses, in industry or for neighborhood solutions. The hydrogen-based heat pump can be integrated into any H2 infrastructure with a pressure difference between hydrogen supply and consumer. The aim is to increase the overall efficiency of the system – simply by converting the energy in the compressed hydrogen into a heat pump effect.

At another stand in Hall 2, the DLR is presenting its research in the field of mobility. For example, the research center has developed a hybrid SOFC battery system that is to be used in cruise ships. It combines the highly efficient solid oxide fuel cell technology (SOFC), which offers significant emission reductions and fuel flexibility, with a lithium-ion battery storage in order to meet the fluctuating energy requirement of a ship.

DLR Thermodynamik, Hall 13, Stand B36

DLR, Hall 2, Stand A48

Fraunhofer IMM also deals with hydrogen as a drive for ships. At the booth of this year's Hydrogen + Fuel Cells, the institute is presenting the Gamma project. As part of the project, a bulk carrier is to be converted so that it can be supplied with climate-neutral fuels and green electricity. Fraunhofer IMM is bringing its experience in the development of compact reformer systems, on which the innovative fuel system for the ship is based.

Ammonia and green methanol are brought on board and then converted into hydrogen with cracker and reform technologies. After cleaning, the hydrogen is converted into electricity in fuel cells, which supplies the ship with electricity and the power generators operated with fossil fuels are replaced. The technological approach of Fraunhofer IMM reduces the size of the reactors by up to 90 percent, which is particularly advantageous for mobile and space-limited applications. The researchers have now managed to convert 700 kg of methanol into hydrogen per day in a compact methanol reformer. The plan is to further expand this service.

Fig. 7: The methanol reformer of Fraunhofer IMM, Source: Fraunhofer IMM

Fraunhofer IMM, Hall 13, Stand C47/1

Hydrogen trade

The gas provider Air Liquide assumes that the purely battery-electric drive, especially for heavy load vehicles, can often not be economical due to high costs for the necessary charging infrastructure. The use of renewable hydrogen in mobility also offers short refueling times and a long range of the vehicles. Therefore, the gas provider expects steadily increasing amounts of hydrogen in the mobility sector. The company creates hydrogen in the 20-MW PEM electrolyzer "Trailblazer." It is said to be the largest electrolyzer in Germany currently connected to a pipeline.

Air Liquide, Hall 13, Stand E27/1

The Westfalen Group, a petrol station operator and provider of gases, is presenting its services for H2 supply to the last mile – whether through electrolysis on site, trailer supply or cylinder and bundle deliveries. The company is active in numerous hydrogen projects. This includes the construction of an electrolyzer in France to supply the steel producer ArcelorMittal. In the Netherlands, Westfalen is cooperating with the energy supplier Alliander in a pilot project in which hydrogen is fed into a natural gas network. Daimler Truck uses mobile trailer solutions from Westfalen for the supply to its fuel cell test stands.

One of the long-term H2 projects is the joint venture Two4H2, which Westfalen founded together with RWE last year. The aim is to build an H2 gas station infrastructure especially for heavy goods traffic. In addition, both companies are still working on an H2 refueling hub in Lingen, which has a public hydrogen gas station and a non-public refueling station for tank vehicles.

Fig. 8: Westfalen delivers hydrogen by trailer, Source: Westfalen

Westfalen, Hall 13, Stand E21/1

System integrators

Siemens is introducing itself at the industrial show as a partner along the entire H2 value chain for OEMs, EPCs, operators, end customers, governments and municipalities. The company wants to support customers in making hydrogen a future-proof, profitable and scalable business. Siemens offers its expertise in digitalization, automation and electrification.

The solutions from Siemens range from the first pilot projects to scalable and standardized blueprints. This also includes the production of green electricity, the network connection and the H2 production. Siemens also provides concepts for storage, transport and use that are tailored to the requirements of hydrogen.

Siemens, Hall 13, Stand C48

Joint stands

Baden-Württemberg is offering companies from the southern German state the opportunity to present their products and services at a joint stand. The-Länd-Gemeinschaftsstand (see Fig. 9) will be organized and supervised by the state agencies E-Mobil BW and Baden-Württemberg International as well as the economic promotion office of the region Stuttgart. All three institutions provide information about various offers regarding knowledge transfer, networking and support for business and science in Baden-Württemberg.

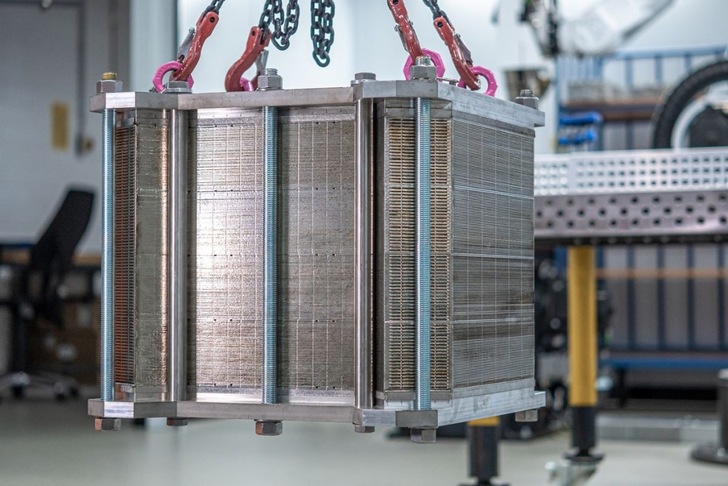

Industrial energy solutions based on hydrogen and fuel cell technologies are the focus of the trade fair this year. Around 40 companies, startups, SMEs, business associations and networks are presenting current trends and developments when using fuel cells and electrolyzers in industry. Highlights are, for example, a low-PFAS membrane production, highly efficient fuel cell stacks and innovative electrolysis technologies.

In addition to H2 and FC technologies, current developments, proven know-how and skills for battery technology, electromobility, research, IT as well as machine, tool and plant engineering are being presented at the exhibitions.

Fig. 10: Around 40 exhibitors will be represented at the Baden-Württemberg stand this year, Source: e-mobil BW

Baden-Württemberg-Gemeinschaftsstand, Hall 13, C78

Author: Jens Peter Meyer