Argonne has been modeling hydrogen fueling for more than a decade. Scientists had estimated that a new technique, called pressure consolidation, could save stations up to 30 or 40 percent of their compressor costs, said Amgad Elgowainy, team leader and principal energy systems analyst with Argonne’s energy systems division.

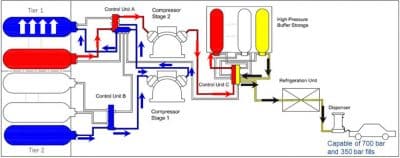

“What we want to do is beef up the storage that feeds the compressor by consolidating hydrogen between storage cylinders,” Elgowainy said. “So, with the same compressor stations in place today, they can fully serve two dispensers side by side instead of just one.”

The new method could cut fueling costs at a dispenser in California from between USD 13 and USD 16 per kilogram to between USD 3 and USD 4, Elgowainy explained. One kilogram of hydrogen had the same energy as one gallon of gasoline, but it could deliver more than twice the miles when used in fuel cell electric vehicles.

“When you look at hydrogen fuel cell vehicles, one major challenge is the cost of fueling infrastructure,” the analyst said. “This technology can reduce the barrier to market by decreasing fueling costs.”

The compressor is the most expensive fueling component, but it’s often oversized and not used to its full potential at hydrogen stations. Large units are a popular choice for dispensing hydrogen more effectively during peak hours, but they then go underused or idle during off-peak times.

Typically, the compressor is supplied from ground storage. When hydrogen is drawn from the ground-stored cylinders, the pressure delivered to the compressor also drops, resulting in low throughput.

…

Argonne received its first patent on the technology in 2017. A second one, still pending, was filed in 2016. This year, the laboratory is planning to test the efficiency of the new method at a commercial station.

“In the near future, we will partner with a commercial entity to demonstrate the technology at one of its fueling sites,” Elgowainy said. “We are in talks with potential partners interested in the technology.”

…

Written by Sue Vorenberg

0 Comments