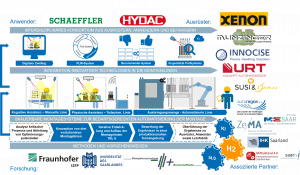

Increasing demand for hydrogen technologies is prompting the need for automakers and equipment suppliers to align and adapt production capacities to meet new requirements. To enable this to happen, it is essential to establish expertise and develop processes and technologies, particularly when it comes to key technology areas like hydrogen production and consumption systems, since gaining a global competitive advantage in the longer term is dependent on the ability to manufacture these systems economically . That’s why the H2SkaProMo joint project is seeking to develop assembly systems for manual, semiautomatic and fully automated production of fuel cell stacks that are readily scalable in terms of their level of automation.If hydrogen technologies are to be used as a means to achieve the climate targets set by the German government, significant effort needs to be put into developing the fields of hydrogen production, transportation and consumption. At present, the production and use of green hydrogen cannot yet be supported commercially. A great deal of potential for lowering costs lies in the fully automated manufacturing of fuel cells in high numbers and the exploitation of scaling effects.

However, as the demand for fuel cells is currently low, this leads to a low utilization of fully automated production systems which in turn results in the payback periods for these pieces of equipment being unviable . Because the demand for fuel cells, and by extension also fuel cell stacks, is expected to fluctuate in the short term and increase sharply in the medium term, assembly systems need to be developed that are easily scalable with regard to output quantity and payback time.

Running alongside this problem is the issue that future refinements to the product are also likely. It is anticipated that such changes will not only affect the geometry of the individual components and the overall system but will influence the type of materials used and the system architecture as a whole. This makes it difficult to perform a simple reconfiguration and thereby hinders the use of the assembly systems for subsequent product generations. Consequently, it is vital to develop assembly systems that both offer the necessary scalability and address the issues of adaptability and reconfigurability.

If we turn our attention to the human factor, it is worthwhile noting that the individual processes involved in fuel cell assembly are often performed by highly qualified technicians who are put under significant strain due to the high degree of product variability, the complex process steps and the high quality expectations for the product. Therefore the assembly systems need be designed with people at their center while also allowing for a certain degree of automation. This includes the consideration and integration of both cognitive and physical assistance systems. Such an approach makes it possible to relieve the mental and physical burden while also involving staff at a shifting level of expertise.[…]

… Read this article to the end in the latest H2-International

Authors: Rainer Müller, Lennard Margies & Klaus Fabian – All from ZeMA – Zentrum für Mechatronik und Automatisierungstechnik gemeinnützige GmbH, Saarbrücken

0 Comments