Synthetic energy carriers like chemically produced methane can make green energy transportable and storable for long periods. The problem: The production is associated with relatively high energy losses. On top of that, the processes up to now also require additional purification of the methane. Researchers from the Swiss materials institute Eidgenössische Materialprüfungs- und Forschungsanstalt (EMPA) want to change that. They have now developed a new concept for methanation.

Synthetic natural gas (SNG), or methane, is a representative synthetic gas – and its production from atmospheric CO2 and renewably generated hydrogen offers enormous potential. Methanation, however, presents some challenges: The catalytic conversion of hydrogen and CO2 to methane results in a product that still contains hydrogen and possibly also CO2. This prevents a direct feeding into the gas grid.

Direct feeding into the natural gas grid

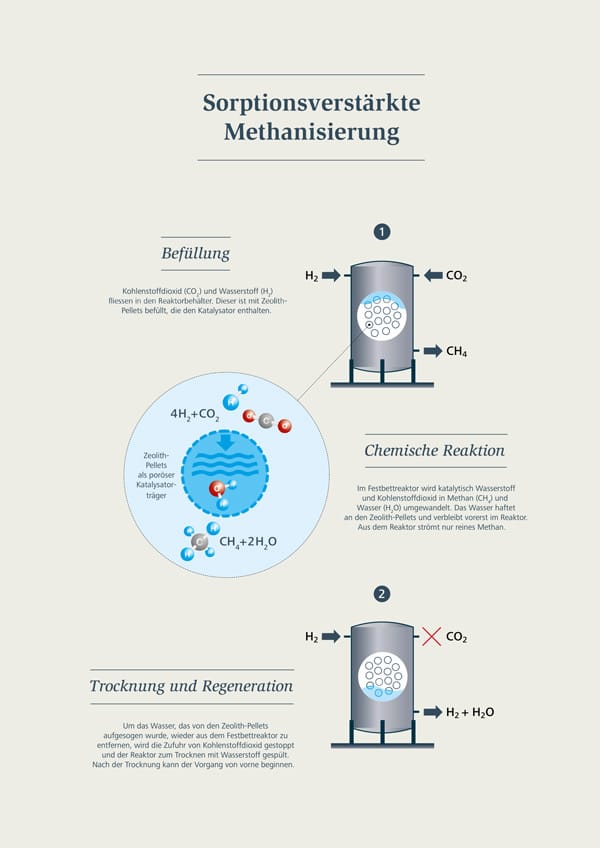

The research team of Florian Kiefer at EMPA have therefore developed a new reactor concept. Hydrogen-free methane is produced by a process known as sorption-enhanced methanation. The idea behind it: The water produced during the reaction is continuously adsorbed on a porous catalyst support during the process. This continuous removal of water leads to only methane coming out as a product. This way, the step to purify a product mixture is no longer needed. The catalyst support material is dried again after the end of the reaction by means of pressure reduction and is ready for the next reaction cycle.

For three years already, the team has been researching a new reactor concept using zeolite pellets. These serve as a porous catalyst support and at the same time adsorb the water that forms during the methanation reaction. “We attain a relatively high purity of the product through the effect of sorption-enhanced catalysis,” according to Florian Kiefer, manager of the methanation project. “This means we are shifting the reaction equilibrium of the Sabatier reaction through a continuous removal of a portion of the products.”

In this case, the water is pulled out. This produces nearly pure methane, or CH4. “The removal of the water continuously takes place in the reactor via adsorption on the catalyst support,” describes Kiefer. In order to achieve this, the catalyst support must have a high water uptake capacity.

What do zeolite pellets do?

With the zeolites used, the researchers at EMPA create exactly this storage property. Zeolites have a high water sorption capacity, including under the conditions in which this reaction takes place. But what kind of material is this? “Zeolites are crystalline microporous aluminosilicates with large internal surface area,” describes the scientist, “and that’s where the high water sorption capacity comes from.”

The adsorption of the water is important, among other things, for feeding SNG into the gas grid, liquefaction into LNG or even for its use in CNG vehicles. Depending on the application, different maximum CO2 and H2 contents of the gas are prescribed, which ideally should be reliably achieved with as little energy expenditure as possible. Furthermore, a most complete conversion possible of the starting materials, H2 and CO2, is important for the overall efficiency of the process. “Alternatively, a separation and recycling of hydrogen and CO2 would be possible, but this is associated with high energy and technical input,” states Kiefer.

One of the decisive advantages of the new reactor concept is the high methane content in the product gas without recycling. In addition, the process can be operated stably at low partial load as well as with fluctuating supply of CO2 and H2. This load flexibility is particularly important for coupling with renewable energies.

Electrolyzers tolerate no impurities

Water for electrolysis in a PEM electrolyzer must be treated, for example though reverse osmosis, since any impurities can damage the membranes. For the treatment of the hydrogen for methane synthesis, however, another electrolysis technology could be used as well, reports Kiefer. To produce 1,000 kg of hydrogen, 8,936 kg of water is needed in theory. If methane is generated from this hydrogen, then theoretically half of the water is recovered.

Synfuels are able to be used in conventional gasoline, diesel or gas-powered vehicles. One disadvantage, however, is the low conversion efficiency. In the production of synfuels from renewable electricity, at this time about half of the primary energy is lost. These losses, according to EMPA, can probably be reduced to 40 to 45 percent in the future. Synthetic fuel therefore only makes sense where direct electrification is not possible. Possible areas of application would be freight transport, cargo ships and aircraft.

But for all the losses, synfuels also have an advantage: They can be easily transported over long distances. In this way, far away renewable energy resources, like in desert areas, can be tapped. The synthetic energy carriers can then also be stored over longer periods without loss. They thus represent an interesting buffer for a national regenerative energy system – which is to be completely or almost completely renewable in less than three decades.

From laboratory to industrial plant

All this is still taking place in the laboratory. From the beginning, however, the focus of the new method has been on scaling. The researchers have therefore been looking for a concept that could also be implemented in large-scale plants. The project was financially supported by, among others, the Canton of Zürich, Avenergy Suisse, Migros, Lidl Schweiz, Armasuisse and Swisspower. Additionally, EMPA has cooperated with various industrial partners.

Crucial for the reactor design and process planning for this is particularly the regeneration time, that is, the time needed for the drying of the reactor. To ensure a continuous methane production, at least two reactors must therefore operate in alternation. For the drying of the reactor, a suitable heat management is also central, whether through dissipation of the heat out of the reactor or through internal storage of the heat in the catalyst bed. Kiefer’s team has filed a patent on this subject. He doesn’t want to or cannot yet disclose any details, however.

“For hydrogen production, you need in addition to renewable electricity also a lot of water,” knows colleague Christian Bach, head of the division for vehicle drive systems. In a demonstration unit is therefore to be obtained directly on site from the atmosphere, in addition to CO2, water for the hydrogen production using a CO2 collector from the spin-off company Climeworks from the technical university ETH Zürich. Such concepts would then in the future also be implemented in desert regions without the aid of liquid water reserves. The Swiss startup Climeworks already operates Orca in Iceland, which is a carbon capture plant with an annual capture capacity of 4,000 tonnes of CO2 from air (see box).

Climeworks is pulling CO2 out of the air

This CO2 direct air capture plant is based on the principle of selective adsorption of CO2 in a material that air is blown through. In the process, hydrogen as well as CO2 is taken out of the air. Through a raising of the temperature, the captured CO2 is expelled from the material and is ready in pure form for methanation. Electricity is required for fans to ensure circulation of the air stream. For the desorption of the adsorbed CO2, heating to about 100 °C is required. “We provide at least half of this heat with waste heat from the overall process,” states Kiefer. And then a heat pump brings the temperature up to the required level with waste heat from the electrolyzer.

The demo plant is to go into operation at the end of 2023. The next steps in the development are already laid out, reports Kiefer: optimization of the entire operating sequence and of the load-flexible operation as well as integration of methanation into the whole process. An accurate assessment of the energy efficiency will only be possible then.

Climeworks launches first large-scale capture plant

In September 2021, Orca started operation in Iceland. This is not a killer whale, as the name might suggest, but a facility for direct capture and storage of carbon dioxide. According to the Swiss company Climeworks, this is the largest capture plant of its type in the world.

The plant consists of eight collection vessels, each with a CO2 capture capacity of 500 tonnes per year. The containers are arranged around a processing hall. In there, all the electronics of the preparation unit are housed such that it can also be operated and controlled remotely.

The required heat and electricity for the air capture process comes directly from the geothermal power plant Hellisheiði. Orca therefore uses purely green energy for capture. The concentrated CO2 is stored in the earth. Through a natural process, the carbon dioxide reacts with basalt rocks and mineralizes this way within a few years. Mid-2022, start of construction for a further project in Iceland was announced. The new plant is called Mammoth.

Author: Niels Hendrik Petersen

Source: EMPA

0 Comments