Increasing volumes of freight transport have resulted in a continuing rise in carbon dioxide emissions within the sector, despite progress being made on fuel consumption and tailpipe technology. Consequently, heavy-duty transportation particularly is in urgent need of fossil fuel alternatives. Fraunhofer IWU, together with 18 other Fraunhofer institutes, is working relentlessly to create the baseline conditions needed for the efficient mass production of fuel cells which are used on board commercial vehicles to turn hydrogen into electricity. As part of the H2GO project, technological solutions will be developed that will enable the rapid scale-up of fuel cell manufacturing. The plan of action is to bring industry and research areas together to form a powerful ecosystem that will allow economic and sustainable fuel cell fabrication. Not only will H2GO develop the industrial mass manufacturing of components using continuous roll-to-roll processing; it will also address issues of circularity. A dedicated subproject is investigating the automated assembly and disassembly of fuel cells so that materials and parts can be recovered and given a second life.

Fuel cell electric vehicles, or FCEVs, have the potential to play a major role in carbon-neutral long-distance transportation in the future: From a technological standpoint, the fuel cell is on a par with current fossil-based propulsion technologies in terms of its ability to carry similar volumes and weights across comparable distances and with similar refueling times. This similarity ensures logistics companies retain their accustomed flexibility in truck deployment. Compared with other emission-free power systems, FCEVs are already financially and environmentally competitive when it comes to heavy-duty transportation – provided there is a successful ramping-up of the market so that hydrogen achieves cost parity with fossil fuels.

For Germany’s manufacturing base, hydrogen has the ability to generate extra added value and thereby establish a far-reaching, sustainable and future-proof area of business. H2GO will help to secure a significant share in the dynamically evolving global fuel cell market for the German economy. A fuel cell industry that is established swiftly therefore has the potential to become a key field of expertise for German businesses. Thus taking greater climate action in the mobility sector also opens up unique opportunities for industrial policy.

It is therefore essential that manufacturing technologies and processes are tightened up to ensure efficient, cost-effective and highly profitable industrial serial production. H2GO will lay the foundations needed for this to happen through research and development into production techniques and preparatory work leading to their industrial application. Importantly, the action plan is targeted at small- and medium-sized enterprises that underpin the entire value chain for fuel cell production, including their application in freight transportation.

Research association of 19 institutes

As an organization, H2GO is formed of 19 Fraunhofer institutes located in nine German states which are offering the use their research expertise and facilities as well as their local networks for the purposes of developing new manufacturing solutions in regional technology hubs. Because the production research association is decentralized, the national action plan allows for the dynamic integration of other initiatives and is reliant on existing facilities. This avoids inefficient duplication, enabling funding to be targeted specifically toward the development of innovative technologies and pre-competitive manufacturing concepts for high-rate fuel cell production.

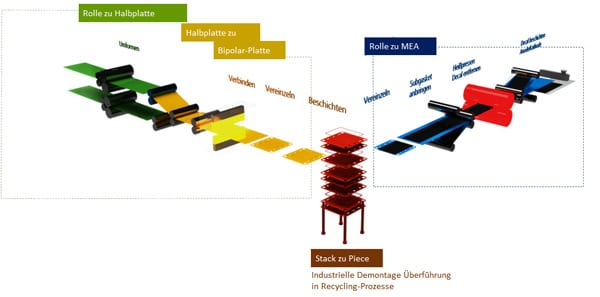

The development goal is to devise concepts that far exceed the solutions that are currently available. These concepts are formulated in technology hubs with different areas of research interest and are combined into four technology groups: R2MEA, R2HP, HP2BPP and ST2P. These represent the major parts of the value chain associated with the manufacture of key fuel cell components, proton exchange membranes (MEA) and bipolar plates (BPP), and will also address the recycling of stacks (ST2P).

The technological backbone of the action plan is the virtual reference architecture for fuel cell production generated by the digital mapping of production modules in the technology groups. This virtual building kit forms the basis for designing, implementing and flexibly adapting application- and type-specific manufacturing scenarios for individual components and entire systems on an industrial scale.

Roll to MEA

The R2MEA group is developing a continuous roll-to-roll or R2R systems technology for manufacturing the membrane electrode assembly, otherwise known as MEA. Here, the focus is on a variety of coating processes and subsequent operations that will be optimized for industrial mass production.

Roll to half plate

The R2HP group is working on forming technologies that can be scaled up to higher unit numbers. For this, different semifinished products or starting materials will be made into half plates in three different process routes using two high-rate forming procedures. The production technologies deployed will be newly created for fuel cell fabrication and optimized with regard to quality and throughput. R2HP will also solve challenges relating to tool design and handling.

Half plate to bipolar plate

The HP2BPP group builds on the production modules of R2HP and utilizes its half plates. The aim is to continuously manufacture high-functionality bipolar plates from these half plates. To make this possible, specific technologies will be developed for the production steps that are upstream and downstream of the R2HP forming process. In addition to quality aspects, the focus here is primarily on higher speeds for the joining, functionalizing, coating and separating steps and on shortening the process chain.

Stack to piece

H2GO is adopting the principles of closed-loop material flows. Together with three other Fraunhofer institutes, Fraunhofer IWU is already asking what production-related changes need to be made to fuel cell product design so that the materials can be disassembled, recycled or, even better, reused. For this purpose, the ST2P group is investigating which machines, systems and processes are required to automatically assemble fuel cell systems as well as to take them apart again at the end of their life without causing damage.

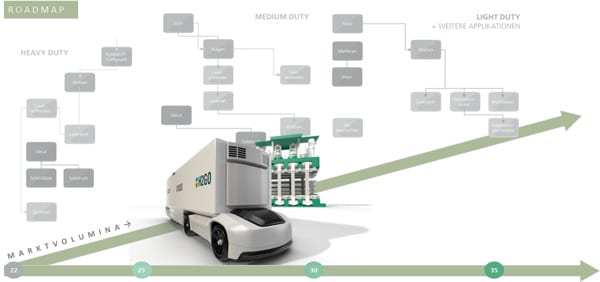

The national action plan is now developing tailor-made scalable production solutions and process chains for the economic manufacture of fuel cells in heavy-, medium- and light-duty applications .

From heavy- to light-duty

When it comes to heavy-duty vehicles (>11.8 metric tons gross vehicle weight), the emphasis is on the technological development of industrial production processes that significantly increase output quantity while also taking special account of the demands on fuel cell life, resulting from the high annual distances traveled. This process chain will therefore use and preform plastic compounds. Flow fields will then be introduced by rolling (R2HP).

Further process steps are laser-based cutting and joining processes and finally a special testing procedure that concludes the bipolar plate production (HP2BPP). This is combined with a membrane electrode assembly that has been manufactured either through a decal coating method using screen printing or via a slot die coating technique (R2MEA).

In the medium-duty application area (gross vehicle weight between 4.5 and 11.8 metric tons), the focus is on the use of stamping as the forming method for the metal half plates (R2HP). The intention is to raise the speed of production and shorten the process chains, for example by using a common tool for stamping and precision cutting (HP2BPP). As a result of these technological developments it is expected that the output quantities will be increased and adapted to growing market demand. This will allow initial scaling effects to be achieved, bringing down costs.

However, in order to exploit the complete range of scaling effects and thus actually achieve cost parity with fossil-based propulsion, ultrafast industrial mass production is needed. This requires the same market volume to be reached as for the light-duty application area (<4.5 metric tons gross vehicle weight). Continuous rolling makes it possible to achieve the necessary ultrafast outputs of up to 100 half plates per minute (R2HP).

Nevertheless, this requires synchronization with the subsequent joining and coating processes (HP2BPP). In addition, pre-coated semifinished products, which encourage a prolongation of bipolar plate life, will be used to stabilize the metal system. These will interact with membrane electrode assemblies, which will be produced using a particularly rapid and innovative method. Here the membrane will be directly coated via an inkjet procedure (R2MEA).

Referenzfabrik.H2

The development of scalable production solutions and process chains not only accelerates the ramp-up of fuel cell technology for different freight transportation scenarios, it also pushes various branches of industry, especially mechanical and plant engineering, to get involved in this new field. One advantage for the companies participating in the H2GO initiative is their access to the model hydrogen factory Referenzfabrik.H2 which is coordinated by Fraunhofer IWU.

Equipped with the real and virtual machines and systems needed for the production of hydrogen systems, this facility acts as a building kit for production technology and is able to support companies in a more agile and targeted way. This greatly reduces the risk of entering hydrogen systems manufacturing as a consequence. Companies can use the Referenzfabrik.H2 to develop further and grow their technologies and gradually start to offer their own products and services as part of the value creation community. Ultimately, the creation of flexible production modules for the scalable industrial manufacturing of hydrogen systems will help the value creation community to make the leap from today’s low part numbers to industrial mass production in the 2030s.

Author: Dr. Ulrike Beyer, Head of the Referenzfabrik.H2 at Fraunhofer IWU, Chemnitz, Germany,

ulrike.beyer@iwu.fraunhofer.de

Source: Fraunhofer IWU

0 Comments