by Hydrogeit | Oct 25, 2023 | Germany, News, Policy

German government steps up the pace

Coordination was hard enough when there were “only” four German ministries dealing with hydrogen – now there are six involved in updating the national hydrogen strategy, plus the chancellery. This participation of so many different departments is surely conclusive proof that hydrogen has become a key plank in the energy transition.

“Being a versatile energy carrier, hydrogen will assume a key role in achieving our ambitious energy and climate targets.” This statement shows the German government’s recognition of hydrogen’s immense importance in the future energy supply and in tackling the climate crisis. It’s for good reason that, three years after the national hydrogen strategy was adopted in June 2020, a redraft has now been approved with content and targets adjusted to match changed conditions.

Advertisements

The update to the national hydrogen strategy, which was enacted by the federal cabinet in July 2023, has, in the government’s words, “created a coherent framework for action for the entire hydrogen value chain – from production to transport through deployment and reuse.” The strategy, also referred to as the NWS, is designed to ensure certainty in financial planning, which provides the foundation for future investment, so that the market for green hydrogen technologies can be successfully ramped up.

At the same time, the NWS recalls that the creation of a hydrogen economy is “a task for the whole of society” whose success “requires contribution from all stakeholders.”

“Hydrogen technologies are not only an important instrument for climate change mitigation. They can enable the creation of new branches of industry with a large number of viable long-term jobs and extensive export opportunities. […] The NWS will thus also help German industry retain and further expand its strong position in hydrogen technologies.”

German government

Specific targets defined

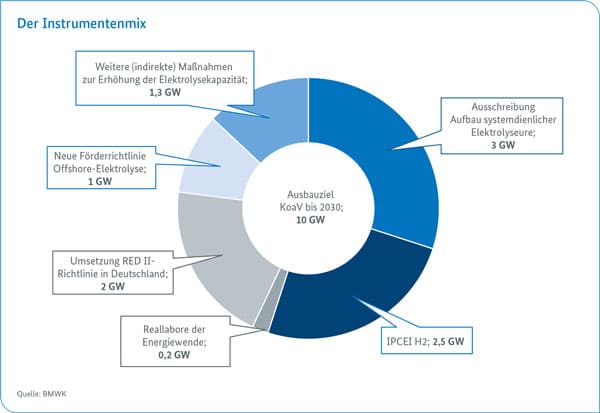

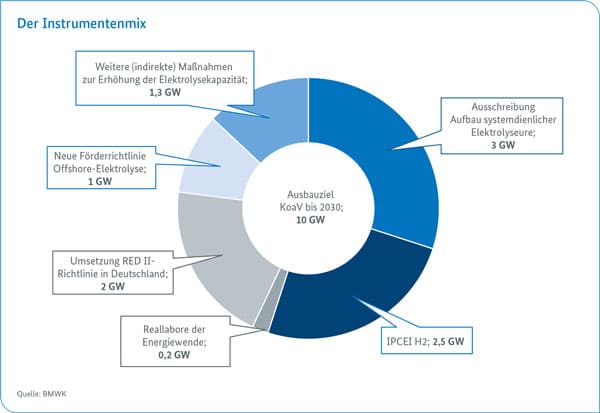

The main 2030 targets outlined in the NWS focus on achieving an accelerated ramp-up of hydrogen and securing sufficient availability of hydrogen and its derivatives. Accordingly, the previous goal of 5 gigawatts of electrolyzer capacity has been raised to at least 10 gigawatts. Remaining demand will be covered by imports which will be the subject of a specially developed import strategy.

What’s more, effective hydrogen infrastructure is to be put place. According to the plans, a hydrogen starter network stretching across more than 1,800 kilometers (1,120 miles) will be got underway by 2027/2028 and supported by funding from Brussels. The network will be composed, in part, of repurposed natural gas pipes as well as newly constructed hydrogen lines. It will form a key part of the European Hydrogen Backbone which will involve hydrogen pipelines covering a total length of around 4,500 kilometers (2,800 miles).

In addition, various hydrogen applications are to be established in different industries – in the power and industrial sectors, in heavy-duty vehicles as well as in aviation and shipping. To allow this to happen, the intention is to create suitable framework conditions, specifically planning and approvals procedures, appropriate standards and certification systems. The stated aim is for Germany to become the leading supplier of hydrogen technologies by 2030.

“We have once again significantly upped the level of ambition.”

German economy minister Robert Habeck

“Hydrogen is the missing piece in the energy transition puzzle. It offers a huge opportunity to join up energy security, net-zero and competitiveness.”

German education and research minister Bettina Stark-Watzinger

“The global market for hydrogen must be fair and different than how the global fossil fuel industry once was.”

German development minister Svenja Schulze

The German government has now departed from its original approach of only financing green hydrogen through tax revenue, a move that has been particularly welcomed, unsurprisingly, by the gas lobby. Other colors of hydrogen are now also set to receive subsidies, albeit only to a limited degree and under certain conditions defined in the small print.

The update to the NWS states: “We also intend to fund the use of green and, insofar as it is needed in the ramp-up phase, low-carbon blue, turquoise and orange hydrogen on the deployment side to a limited extent while taking into account ambitious greenhouse gas limits, including emissions in the upstream chain and the ability to meet statutory net-zero targets.”

Bettina Stark-Watzinger, German education and research minister, called this a “pragmatic and technologically unbiased” decision that allows initial use of “all climate-friendly types of hydrogen.” This, she explains, will help Germany on its way to becoming a hydrogen nation.

Her colleague, German development minister Svenja Schulze, went one step further by saying: “Wherever wind and solar power is produced for hydrogen, momentum will be given to the energy transition at ground level and the local population will be supplied with electricity. And wherever seawater is desalinated for hydrogen, the nearest town will be supplied with drinking water. From a development perspective it’s clear: Hydrogen from renewables is not only the best choice for the environment, it is a cost-effective domestic energy source that also leads to better development in the Global South. We will therefore help our partner countries have a fair share of involvement in the new international market for hydrogen.”

Existing structures remain

To allow all this to happen, recourse is being made to existing institutions. For example, a “hydrogen guidance center” has already been set up that enables inquirers to receive advice on funding by phone or email. The committee of state secretaries for hydrogen acts as a decision-making body for the NWS and takes corrective action where necessary. It meets on a case-by-case basis as and when needed, which in the past was only rarely. The central body is the National Hydrogen Council, an independent, cross-party advisory committee with 26 high-ranking experts from industry, academia and civil society. The council is supported by the Coordination Office for Hydrogen.

Chair of the National Hydrogen Council, Katherina Reiche, explained: “It is an important milestone that the German government is ambitiously extending its national hydrogen strategy. […] Only hydrogen allows us to maintain value chains and ensure that key industries remain in Germany. […] Companies only invest if they have long-term planning certainty. We must therefore already look beyond 2030. According to council forecasts, the need for hydrogen and hydrogen derivatives will, by 2045, have risen to between 964 and 1,364 terawatt-hours. The Inflation Reduction Act in the USA and similar regulations around the world will accelerate the development of comprehensive value chains on an industrial scale. In view of rapid progress made in other countries, the German government should move away from exclusively focusing on flagship projects. What is more important is to create effective incentives to quickly scale the hydrogen economy and the development of new business models.”

On the subject of the – at times – fierce debate about the use of hydrogen in the heating sector, the council said that it endorses municipal heating plans as a crucial planning tool for encouraging the heating sector to shift away from fossil fuels. In its view, a successful transformation of the heating sector would require all technology options: heat pumps, heating networks, renewable heat and hydrogen. Thus all technologies should be granted equal footing as compliance options in Germany’s building energy law and be considered when undertaking infrastructure expansion.

The council added that rigorous training is needed for the specialist workforce required, both at university level and within the area of vocational training and continuing education.

Criticism and ideas for improvement

While the German government proudly unveiled the NWS update, the opposition, as expected, deems the 34-page document to be a flop. The CDU’s vice chairman, Andreas Jung, explained to German newspaper Tagesspiegel: “Hydrogen is so important for the economy and net-zero that it now needs a double-whammy.” Here Jung apes the “double-whammy” expression used by Chancellor Scholz when announcing his EUR 200 billion relief package to help with the cost of living. Jung’s criticism that the government was acting “halfheartedly” and would operate on the basis of “centrally controlled allocation” falls flat, however, since the targets set are highly ambitious and the NWS is ultimately only putting a framework in place – and does not include technical guidelines.

For example, it is understood that a “hydrogen acceleration law” will get off the ground this year to enable the installation of “further terminals only for hydrogen or its derivatives” as previously with LNG terminals. A “national port strategy” is expected to pinpoint the relevant hubs for the future hydrogen economy.

Jorgo Chatzimarkakis, CEO of Hydrogen Europe, therefore believes Germany is on the right course to be able to achieve “the broad use of green hydrogen in industry and the heating sector within nine years.” However, he thinks specific improvement measures are necessary, for instance better integration of H2 Global into the EU’s hydrogen bank in order to leverage European Union tendering processes as well as off-take agreements for temporarily nationalized companies, such as Uniper, that can contribute toward security of supply.

Additionally, Chatzimarkakis sees the need to shorten the IPCEI approval times at EU level and in Germany. He also suggests launching an “EU tax credit club” for hydrogen – as a semi-response to the Inflation Reduction Act in the USA, which cannot be introduced in the EU in a similar form due to tax regulations.

Contributions to the NWS 2.0 were made by the following German government departments: the economy ministry, the transportation ministry, the education and research ministry, the environment ministry, the development ministry as well as the foreign office and the chancellery.

Author: Sven Geitmann

by Hydrogeit | Oct 25, 2023 | Germany, News

HPS inaugurates home with solar hydrogen storage system

In Schöneiche, a suburb east of Berlin, the first self-sufficient hydrogen house is starting practical testing. A solar year-round storage tank should cover the demand for the modern timber house. The goal of the FlexEhome research project is to show how a home can be self-sufficient with electricity and heat if it is suitably well insulated. In the scope of this project, the participants are also testing grid-serving services.

The photovoltaic system of the brand new single-family home in the street Schillerstraße was deliberately designed to be very large with a total output of almost 30 kilowatts – so it can generate a solar energy surplus for the production of clean hydrogen. Currently, most buildings with photovoltaic systems and batteries produce too much electricity in the summer, however, not enough in the winter months. So far, there is no seasonal storage.

Advertisements

In a practical test, the FlexEhome research project will now demonstrate that it can be done differently: Electricity should only be released into the grid or taken out when it is also useful for the grid. This is possible due to a significantly larger storage capacity compared to batteries and the production of hydrogen, which can be stored for longer periods of time. Thanks to this flexibility, grid stability is improved and the need for expansion of the decentralised distribution grids is minimised. In this way, the residents of such a building contribute to power grid stability and supply security.

“In the future, such decentralised flexibilities will be indispensable for the success of the energy transition,” emphasised Zeyad Abul-Ella, head and founder of Home Power Solutions (HPS), at the ceremonial presentation of this solar hydrogen house. An essential component of the project is the long-term storage picea from HPS, which stores the surplus electricity from the solar system in the summer in the form of hydrogen by means of electrolysis. In winter, the green gas is converted back into electricity and heat via the fuel cell.

AEM electrolyser from Enapter

The hydrogen is produced by an AEM electrolyser 2.0 from the German-Italian manufacturer Enapter. The module can start and ramp up relatively quickly. The battery storage is a German-made lead-gel accumulator with a net capacity of 20 kWh. Lead – although a toxic heavy metal – has the advantage that there is already a well-established recycling system – especially for starter batteries from motor vehicles.

Civil engineer Abul-Ella developed the complete system of electrolyser, fuel cell, hydrogen tank as well as lead storage and ventilation unit himself almost ten years ago. However, the picea system is not cheap, costing 120,000 Euro for the full system. Nevertheless, sales of the so-called all-season power storage units have increased strongly in recent months. More than a hundred units are already in operation, and more than 500 have been ordered.

The Berlin-based company can hardly keep up with the orders. The waiting time is currently about twelve months. The production of HPS is therefore to be expanded further. Also because of projects such as FlexEhome: Participating partners are, for example, the heat pump manufacturer Vaillant, the timber house builder Albert Haus and the Technical University of Berlin.

Solar facing to the east-west and south

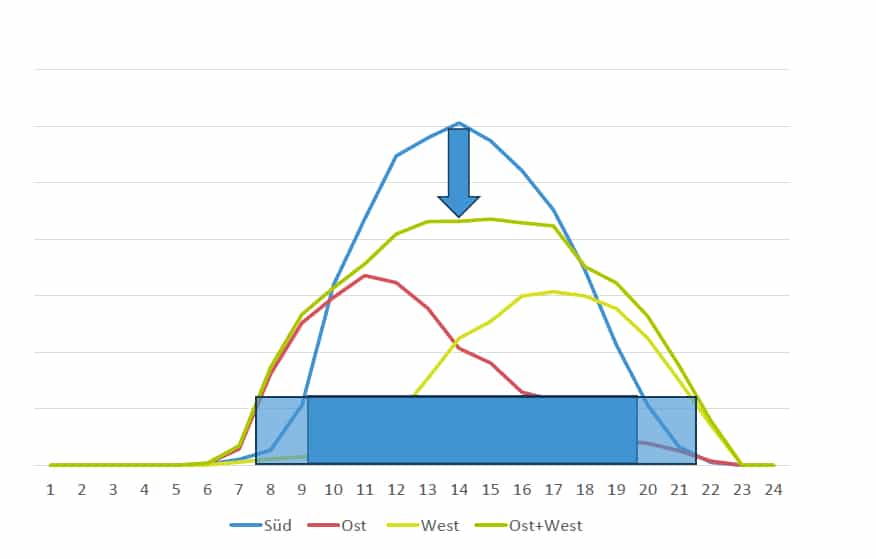

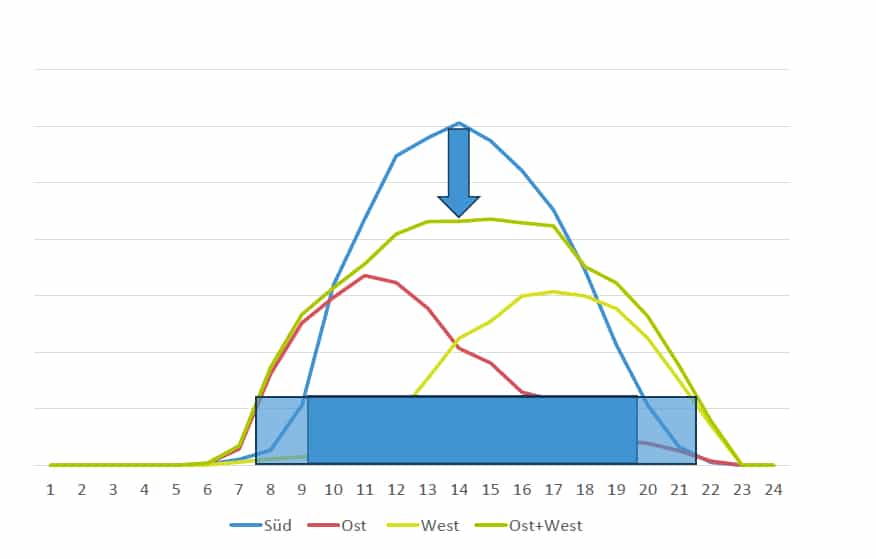

In order to smooth out the solar harvest from the roof already during production, the majority of the photovoltaic modules with 27.4 kilowatts were installed as a roof-integrated solution facing east-west. In addition, seven modules with a total of 2.4 kilowatts are located on the balcony railing facing to the south. Both together reduce the PV midday peak by 30 percent (see Fig. 2) – and therefore extend the runtime of the electrolyser by four hours per day in summer. “This increases the hydrogen yield by as much as 40 percent,” says Daniel Wolf from HPS. The engineer is the network coordinator of this innovative project.

The electrolyser with a total of four bundles of pressurised gas cylinders, each with an electrical output of 300 kWh (see Fig. 3), is located in a timber house on the north side of the detached house to store the H2 gas from the summer months for the winter months. According to the calculations of Daniel Wolf, the hydrogen storage tank would be completely full again by July. The space heating demand of the almost 150-square-metre home is around 40 percent below that of a KfW55 house. This high insulation standard is also necessary so that the house can supply itself with electricity and heat all year round. This is the key and the basis for full green supply.

But the long-term storage of electricity should also pay off economically in the future – through trading on the electricity market. Because there are very high exchange electricity prices every now and then, as on some days in December 2022, when it was the equivalent of 60 ct/kWh. On the other hand, there is the extreme of negative electricity prices, such as at the beginning of June 2021, when minus 5 ct/kWh was requested. This is where the H2 storage of HPS, which has reserves at all times, could pay off, says Daniel Wolf.

The (TU) Technical University of Berlin monitors all energy flows

The hydrogen is turned back into electricity and heat in a combined heat and power generation plant, where waste heat is also used. In combination with a heat pump, this ensures a year-round supply of the house with self-generated solar power. The interaction with the heat pump in particular will be investigated in greater detail through this project in the coming months.

Soon, a family of four will be living in the project house for rent. They will pay a lower rent compared to the local area, but will have to allow professional visitors and technicians access to the technical room from time to time by appointment. In order to document the full supply and a grid-serving feed-in, over the next few months the TU Berlin will also monitor all energy flows in the house in detail.

The researchers will continue to support the project until at least the end of 2024. In addition to the energy balances, they also look at the CO2 emissions. “In the end, we want to assess whether a building like this is worthwhile for climate protection,” says Alexander Studniorz from the TU Berlin. The scientists are conducting a life cycle analysis for this purpose. The scientist’s assumption is that it is the temporal shift in electricity consumption that will have a positive impact on the CO2 balance. This is because, unlike in homes with a PV system and a battery storage system, no additional grey electricity needs to be drawn from the grid on a cold winter night when many fossil-fuel power plants are in operation. “The seasonal buffer in particular, in combination with the heat pump, therefore guarantees low CO2 emissions all year round,” predicts the TU researcher.

Author: Niels Hendrik Petersen

by Hydrogeit | Sep 8, 2023 | international, News, worldwide

Austria focuses on pioneering hydrogen research

Austria’s first and leading hydrogen research center HyCentA began life in 2005. Now promoted to become part of the COMET funding program (Competence Centers for Excellent Technologies), it is continuing its research on the campus of Graz University of Technology as a K1 center of excellence.

Advertisements

The Hydrogen Research Center Austria located at Graz University of Technology, better known as HyCentA, is Austria’s top research center for hydrogen technologies. Since it was founded in 2005, HyCentA has specialized in developing novel technological solutions for electrolysis, hydrogen storage and fuel cells, delivering innovations in cooperation with partners and supporting technologies as they progress from initial idea to market maturity.

Alexander Trattner, scientific director of HyCentA, explains: “We want to push the sustainable hydrogen society much further because we’re convinced that green hydrogen has to be part of the solution for a net-zero energy system. Approval as a COMET K1 center allows us to carry out extensive research into hydrogen technologies that are especially relevant for the future: electrolyzers, storage systems and fuel cells. We’re also able to concentrate more on a holistic view of hydrogen within the areas of electricity, heat supply, transport and industry. The COMET K1 program enables long-term research to take place at HyCentA, underpinned by decades of experience in research and development as well as hundreds of successfully completed projects.”

COMET network

COMET’s mission is to build bridges between science and industry for a sustainable future. As Austria’s flagship science and industry program, it is intended to support pioneering research. The network funds the setup of technological centers of excellence referred to as COMET centers.

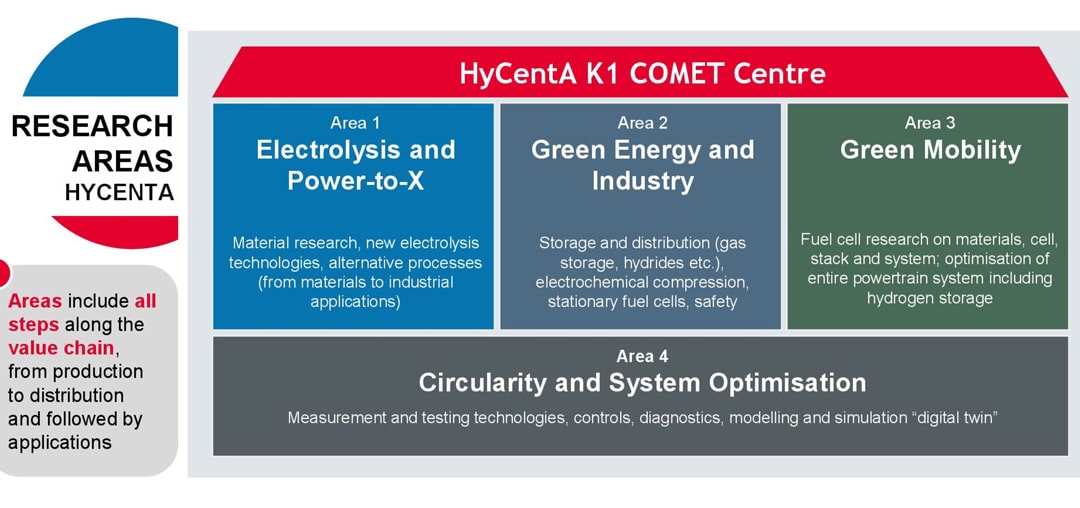

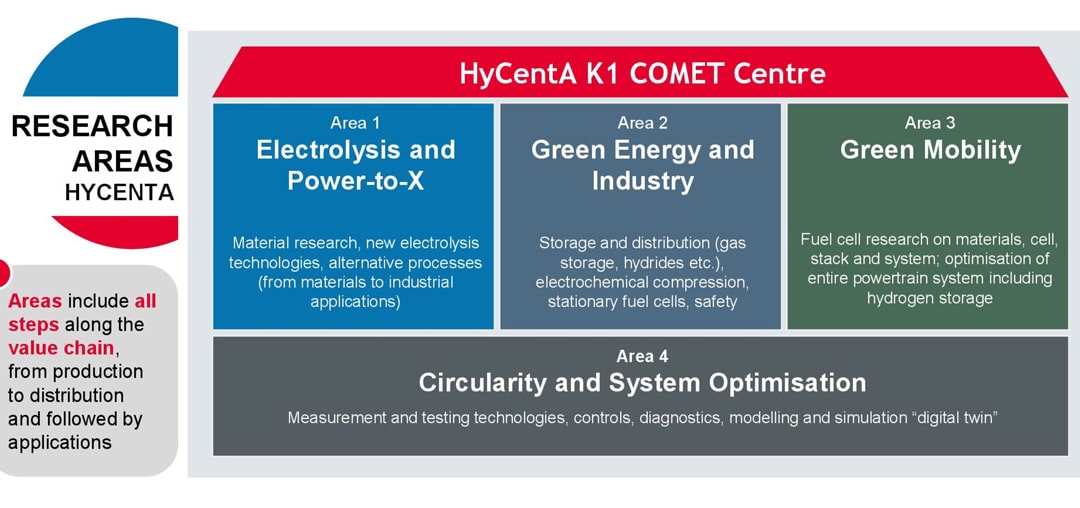

The work conducted by the 80-member team at HyCentA is divided into four areas. The goal is to lower the cost of technologies, reduce degradation and raise the efficiency of electrochemical cells. In addition, the intention is to identify the ideal combination of key technologies and optimization potential by coupling the energy, industry and mobility sectors. Ultimately, it is hoped that this will enable a higher degree of self-sufficiency in renewables, increase the resilience of the energy system and safeguard international competitiveness through in-country value creation. A total of around 40 leading national and international businesses and academic partners are contributing to the research alongside HyCentA as part of the COMET program’s work on hydrogen technologies.

Area 1: Electrolysis and Power-to-X

Area 1 covers all technologies that support the sustainable and emission-free production of hydrogen and chemicals for storing hydrogen. The main technologies for electrolytic hydrogen production are the more developed techniques of alkaline and proton exchange membrane electrolysis (AEL and PEMEL) as well as applications with mid-levels of technology readiness (anion exchange membrane and solid oxide electrolysis: AEMEL and SOEL) and promising methods with a low degree of readiness (proton-conducting ceramic electrolysis: PCCEL). Other research focuses on approaches for splitting water by means of solar energy (photoelectrolysis) and the electrochemical manufacturing of chemicals such as hydrogen peroxide and ammonia.

The aim is to further develop the technologies, starting with the materials and progressing through the cell and stack and continuing all the way to system level. Although the general goals of increasing longevity and efficiency and lowering cost apply to all technologies, the specific research approaches vary. When it comes to raising efficiency, it is the design and operational strategies that need to be optimized. For extending the life of electrolyzers, on the other hand, the focus is on accelerated aging tests. Meanwhile, for improvements in production processes, the research sets its sights on increasing the automation of manufacturing and assembly processes.

Area 2: Green Energy and Industry

Area 2 concentrates on key technologies that are essential for hydrogen applications in the energy and industry sectors. Under consideration are stationary and mobile storage technologies based on compressed gas storage as well as metal hydride and liquid storage. Synergies from bringing together stationary and on-board applications are exploited by developing an intelligent combination of distribution and logistics systems with stationary forms of infrastructure. Investigations are carried out into areas including electrochemical compression and purification in addition to power conversion using stationary fuel cells. Alongside the efficiency of the technologies examined, the reliability and safety of systems are also a key research priority.

Area 3: Green Mobility

The focus of Area 3 is on fuel cell and hydrogen storage systems, particularly for mobility applications. These comprise PEM and AEM cells, stacks and systems as well as optimized forms of existing and alternative storage systems. The research work aims to generate a deeper understanding of the mechanisms of fuel cells and storage systems so the problems of performance, degradation, cost and industrialization can be better appreciated and solved using suitable countermeasures.

Relevant results for the interface definition at the level of vehicle integration and refueling infrastructure are used to create the best possible basis for future developments. Key knowledge is used to improve production and manufacturing so that market readiness and viability can be rapidly achieved.

Area 4: Circularity and System Optimization

Area 4 develops seamless tool chains in order to examine and optimize resilient, cross-sector energy systems based on renewable primary energy and hydrogen. These simulation tools allow operational strategies for power-to-X plants to be devised and business cases created.

Innovative testing and measuring instruments for fuel cells and electrolysis as well as underlying measuring and diagnostic methods are developed for the purposes of gaining knowledge about degradation, state of health and predictive maintenance. Efficient and cost-effective measuring tools and systems are deployed for applications across the entire hydrogen value chain, and extensive knowledge is acquired about the suitability and compatibility of materials in conjunction with hydrogen applications.

Analyses and concept developments are translated broadly into systemic and economic market models and recycling options for the purposes of creating a circular economy. The future potential of recycling processes and technologies is also assessed and evaluated on a representative small scale. An environmental performance model is being developed for recycling scenarios which methodically compares and contrasts new and recycled materials.

Hydrogen, fuel cell & electrolyzer test center

Testing is an integral part of the HyCentA research portfolio. The center’s facilities are used to test and inspect performance, safety, degradation behavior and reliability in real hydrogen operations. This work is undertaken by numerous labs and testing areas which meet the unique and stringent demands of established testing and inspection routines as well as specialist customer requirements.

The various tests which can be conducted in these facilities include quality assessments, calibration services, performance and efficiency tests, safety tests, service life tests and examinations under real environmental conditions. Among the amenities at the 1,200-square-meter (12,900-square-foot) test center are two single-cell electrolysis test stations, two short-stack electrolysis test stations, a high-pressure test station up to 1,000 bar with climatic chamber, two multifunctional test stations, a fuel cell cathode subsystem test station, a fuel cell system test station up to 160 kilowatts with climatic chamber, a gas analysis lab, an analytical and electrochemical lab, an electrochemical compression test station, a 350-bar and 700-bar hydrogen refueling station, a test cell for hydrogen permeation and an autoclave for hydrogen material compatibility analysis of samples.

TU Graz and HyCentA

The HyCentA research center aims to benefit the community as a whole. Researchers work in close cooperation with Graz University of Technology, also known as TU Graz, particularly when it comes to industrial research into electrolysis, fuel cells and hydrogen infrastructure. HyCentA shareholders are TU Graz, which owns a 50 percent stake, Magna, OMV and the combustion and thermodynamics research organization FVT. The COMET center of excellence is financed by the Austrian government – specifically the climate action ministry and the economy ministry – and the states of Steiermark, Upper Austria, Tyrol and Vienna. The Austrian research promotion agency FFG has been in charge of program management for more than 20 years.

TU Graz is Austria’s most tradition-rich technical and scientific institution for research and education. The university has been successfully researching electrochemistry and hydrogen for more than 50 years. Today, the TU Graz campus is home to a 160-member team working in hydrogen research and across its unique lab and research facilities, making it one of Europe’s leading establishments. The university covers the entire value chain for the renewable hydrogen industry, from production via storage and distribution to deployment, and is a one-stop shop for hydrogen technology research –from the fundamentals through applied technologies and systems.

www.hycenta.at

Author: Alexander Trattner, HyCentA Research GmbH, Graz, Austria, trattner@hycenta.at

by Hydrogeit | Sep 8, 2023 | Germany, News

EU projects reveal need for new safety measures

The results of the European Union’s HyResponder and HyTunnel-CS projects have been awaited with great anticipation. Numerous experts from industry, the fire service and research institutes been involved in these initiatives over the past few years, tasked with tackling the issue of fires and accidents connected with hydrogen applications. Now the International Fire Academy, the IFA, writes: “Hydrogen vehicles in tunnels: great danger for emergency response personnel.”

Advertisements

The publication of Germany’s national hydrogen strategy saw the German government set out a framework for action for the future production, transport, use and reutilization of hydrogen and related innovations. Hydrogen can make a significant contribution to mitigating climate change – as a fuel for cars, a feedstock for industry or a fuel for heating systems. A multifaceted energy carrier, it can be applied across all sectors and therefore has a key role to play in the energy transition.

In power-to-gas plants, a carbon-neutral process is employed to produce green hydrogen using renewable energy, allowing this energy to be stored effectively in the gas grid and carried onward. Hence its proponents are suitably upbeat about the technology.

However, hydrogen is – as a quick glance at the safety data sheet will tell you – a highly flammable gas and one which is now being stored and transported with increasing frequency and in ever-larger quantities. This poses a challenge for fire services and public authorities when handling approvals procedures and inevitably when responding to emergency situations, as the following call-out examples show:

- Truck catches fire at a hydrogen refueling station

- Two persons seriously injured following a hydrogen tank explosion

- Hydrogen refueling station exploded

- Difficult salvage operation – accident with “hydrogen vehicle”

Fire services are well used to dealing with traditional fuels such as gasoline and diesel on their rescue missions. Alternative fuels like liquefied natural gas, better known as LNG, or hydrogen have so far played only a very minor role, which is why emergency crews have fairly limited experience of them.

Now the energy transition is starting to gain momentum. Due to the conflict in Ukraine, the demand for LNG and hydrogen has risen sharply. In addition, natural gas grids are expected to convey hydrogen in the future, initially in blended form. A great deal of technical research and regulation will be needed to make it possible, and is currently being agreed and established in various committees.

This requires appropriate resources to be made available to public authorities and emergency organizations in order to handle the arrangements, train up staff and ensure the provision of special firefighting equipment.

We have observed that there are already established hydrogen applications for which fire crews often do not yet have the appropriate skills to carry out an emergency response.

HyResponder and HyTunnel-CS projects

In the past few years, the EU’s HyResponder project has developed a European Emergency Response Guide which is currently being presented at a country level. In Germany, an event took place in Oldenburg at the end of May 2023 in order to communicate the proposed hydrogen emergency responses to German firefighting experts. The same event was held in Austria in April.

The most important outcome from the European HyTunnel-CS research project, to which the IFA contributed its views from a fire service perspective, is: “Firefighters can protect themselves against smoke, heat and fire spurts, but not against the blast waves from explosions of hydrogen vehicles in tunnels. Therefore, it is vital to keep a safe distance. However, how can people be saved and fires be fought effectively? There is still no satisfactory answer to this question – although more and more hydrogen-powered vehicles are being registered. That is why the fire services need to work on suitable solutions immediately.”

Alongside recommendations from the research projects, there are other national and international means of support for emergency services, for instance ISO 17840 – the first global standard for firefighters. Knowing how the energy is stored on board a vehicle can mean the difference between a successful rescue and a possibly unexpected explosion, gas leak, shooting flame or a fatal electric shock.

Several hundred thousand users have downloaded the Euro Rescue app. It offers access to 1,400 vehicle rescue sheets in four languages. The international association of fire and rescue services CTIF is pushing its distribution and takeup.

Nevertheless, this presupposes that rescue teams are able to identify the type of vehicle. In cases of fires occurring in tunnels or underground parking lots, this is difficult to accomplish. It is this particular circumstance the IFA was referring to in the earlier quotation. This is because fire crews would proceed as usual and then suddenly happen upon a fuel cell vehicle. Even if the correct rescue data sheet is found, the information about the necessary safety distances for emergency crews in the event of a hydrogen vehicle fire can be best described as “leaving room for improvement.”

When dealing with fires and accidents, the overall scenario always has to be considered. This must include the area surrounding the rescue site and account needs to be taken of this in response planning. A fuel cell bus, for example, could be on fire at night in the parking lot because it is parked next to another burning vehicle. The hydrogen bus is not the cause here, yet it does make the scenario much more serious. Two basic situations need to be contemplated: One in which hydrogen equipment (hydrogen bus, hydrogen car) is itself the cause and the other, much more likely case where hydrogen equipment will be affected by an external event. It is essential that the approvals procedure takes both variations into consideration.

Artificial intelligence has great potential

On the other hand, new digital applications, particularly artificial intelligence or AI, are offering up possibilities for rapid information gathering in the future which could support the emergency response. The long times taken by public authorities to process approvals have come under much criticism. Policymakers are promising to speed up procedures significantly in this respect. Here too, AI can come into play and save a lot of time.

In particular, a suitable AI module can allow the fire service to quickly analyze the documents received and check plausibility. Robots and drones – with AI – can bring decisive benefits for emergency responses in explosive ranges. For example, a robot can scan an underground parking lot. Especially relevant here is the ability to identify fuel cell vehicles in underground parking lots and tunnel systems without endangering emergency crews.

One solution would be to fit vehicles that run on alternative fuels with a chip so that robots or drones are able to identify the vehicles more quickly. Measurement technology on the robot could also be used to detect leaking hydrogen.

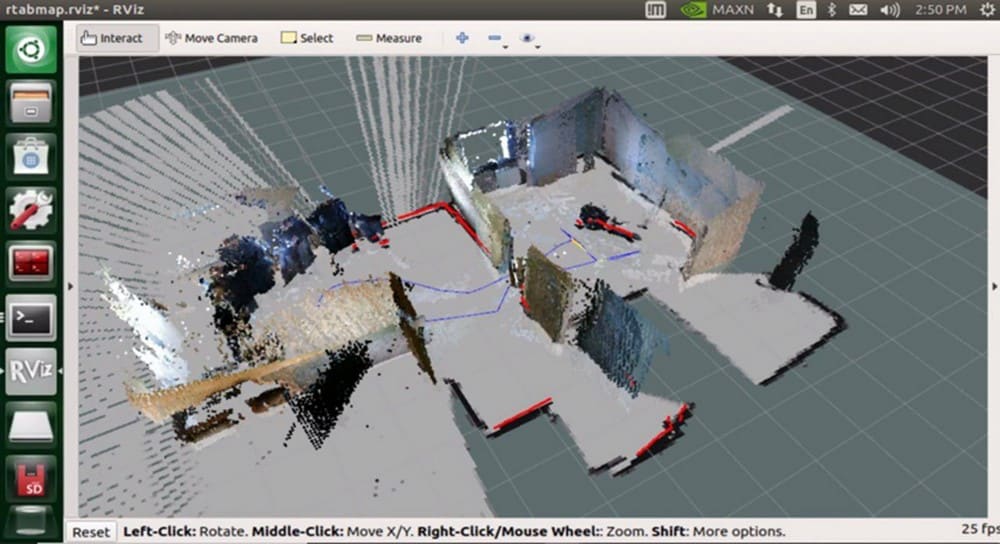

Explosive situations cannot be practiced in real life which is why training using virtual reality or augmented reality techniques lends itself to this purpose. As Figure 3 shows, useful training for incident commanders can be carried out with regular free-of-charge programs.

Balancing act

If the fire service needs training and special resources, it doesn’t necessarily mean that the hydrogen technology is faulty or susceptible. It is the new scenarios, such as a multi-vehicle accident in a tunnel involving a hydrogen truck or bus, that are significantly increasing the risk for responders.

This is all “politically controversial” in terms of getting action, since the desired message is that hydrogen is virtually problem-free. Financial support for emergency response is “not likely” to be provided. Emergency service organizations are increasingly confronted with a variety of new technologies and fuels. Many different fuels are being used in parallel during the transitional phase. For those working in fire and hazard prevention and in incident planning, this often means they come across new situations and are learning by doing. Not only does workplace health and safety need to be ensured for staff at hydrogen refueling stations and tanker drivers but equally so for emergency crews as part of a risk assessment.

How much extra training do we want to provide our fire service members? At the moment there are still no special training facilities in Germany. The German interior minister warns of “attacks” on energy infrastructure, and violent action by activists also needs to be taken into consideration. This requires incident planning by fire services. Alternative forms of energy are “closely” linked to this: In terms of emergency response, it makes sense to exploit synergies, for example by including LNG and CNG in hydrogen training courses.

Reference(s)

- mdr.de/nachrichten/sachsen/chemnitz/zwickau/brand-tankstelle-lkw-zapfsaeule-meerane-100.html

- kleinezeitung.at/oesterreich/5779092/Niederoesterreich_Zwei-Schwerverletzte-nach-WasserstofftankExplosion

- heise.de/autos/artikel/Wasserstofftankstelle-in-Norwegen-explodiert-4445144.html

- noen.at/moedling/schwierige-bergung-unfall-mit-wasserstoff-fahrzeug-gumpoldskirchen-wasserstoff-bergung-133570154

- ifa-swiss.ch/magazin/detail/wasserstoff-fahrzeuge-in-tunneln-grosse-gefahr-fuer-einsatzkraefte

- ISO 17840: The First Worldwide Firefighters’ Standard | CTIF – International Association of Fire Services for Safer Citizens through Skilled Firefighters

- Petter, F.: First on site: Decision-making training for incident commanders in vehicle fires, internal study, unpublished

- 200,000 users have downloaded the Euro Rescue app – access to 1400 vehicle Rescue Sheets in 4 languages | CTIF – International Association of Fire Services for Safer Citizens through Skilled Firefighters

Author: Franz Petter, Chief Fire Officer, Hamburg, Germany, FranzPetter@aol.com

by Hydrogeit | Aug 1, 2023 | Germany, News

Largest H2 ecosystem will appear in Thüringen

In the heart of Thüringen – around Erfurt and the northern part of Thüringer Becken – is where TH2ECO is situating the regional hydrogen market currently in establishment. A partnership consortium of regional specialists has been developing this project since 2021. The partners from different renewable energy fields are grid operators as well as energy and power suppliers who are driving forward the building and expansion of a sustainable H2 infrastructure and the establishment of the new energy carrier hydrogen. With it from the start has been Kilian Fromm, project manager at Green Wind Innovation, to whom German economy minister Robert Habeck handed the H2Eco Award for this project during this year’s Hannover Messe.

Advertisements

TH2ECO aims to create a regional hydrogen market that demonstrates how the complex system of a market with various economic, technical and regulatory requirements over the complete value chain –from green H2 production to its use – can work for the region and how the local value creation can be integrated in a supraregional market in the long term.

TH2ECO is committed to three core objectives: decarbonization, regionality and sustainability. Through ramp up of a low-carbon economy, CO2 emissions in Thüringen will be significantly reduced. With a grid-serving integration into existing grids, already existing structures in the region will be integrated.

From production to use

Cooperating in the partnership and in coordinated project direction are, at this time, three energy providers (Green Wind Innovation, Boreas Energie, TEAG Thüringer Energie AG), three gas network operators (Ferngas Netzgesellschaft, SWE Netz, TEN Thüringer Energienetze) and a gas storage operator (TEP Thüringer Energie Speichergesellschaft) as well as several customers. The main areas for use of the H2 are transportation, the centralized heat generation as part of the district heat supply for Erfurt (SWE Energie) and in the industrial sector:

- Transport: At freight village Güterverkehrszentrum (GVZ) Erfurt Ost with a refueling station for commercial vehicles from Jet H2 Energy as well as intralogistics applications and use in rail transport

- Industry: businesses in industrial park Erfurter Kreuz

- Heating: GuD-Heizkraftwerk of Stadtwerke Erfurt (SWE) for heat and power generation; blending in the natural gas distribution networks

Phase 1: Gas pipeline already under conversion

TH2ECO is divided into three phases, which illustrate the building stages of the emerging hydrogen market. In the initial phase up to 2025, it is planned that three electrolysis plants with a combined capacity of 25 MW go into operation in Thüringer Becken. The H2 transport is primarily being carried out via the existing 42-km natural gas pipeline currently under repurposing for 100 percent green hydrogen. In the city of Erfurt, SWE Netz is providing further supply via H2 lines.

GuD-Heizkraftwerk in Erfurt, the industrial park in Erfurter Kreuz and the local natural gas grid of municipality Kirchheilingen will consequently be connected via this pipeline. The natural gas rock reservoirs in Kirchheilingen will be unidirectionally integrated, which has already been investigated for H2 use and the feasibility was confirmed. Also the GVZ in Erfurt will already be supplied in the initial phase by the second quarter of 2025, where since the new gas grid connection is yet to be built, delivery is initially to take place via high-pressure trailers.

Phase 2: Expansion to 40 MW generation capacity

In the second phase, to expand the regional H2 market that has emerged, an expansion of generation capacities to 40 MW is envisaged during ramp up of the German hydrogen market. The H2 supply network is to be expanded, for which the gas distribution network of provider TEN Thüringer Energienetze will be connected and the H2 storage used bidirectionally. On the consumption side, Erfurter Gasnetz will be linked in and line connection to the GVZ will occur. Use of H2 in the GuD-Heizkraftwerk will be heightened and rail transport structures incorporated.

Phase 3: Supraregional integration

Subsequently, the project TH2ECO will be scaled further through the uptake of additional regional H2 generation and H2 importing from other regions. The network will be integrated into the supraregional H2 backbone, so supply to large industrial operations is guaranteed and each of the municipal utilities can achieve climate neutrality.

Exemplary for Germany

A high degree of innovation has been shown with TH2ECO already in the initial phase: Due to the potent network across the generation and consumption sides, market structures are emerging on both sides of the value chain that differentiate TH2ECO from other projects.

With three H2 producers and various consumers in different industries, a variety of new questions arise, which are approached in an exemplary manner in the TH2ECO project, thus constituting a blueprint for the German H2 market:

- How will practical contract structures between H2 producers and consumers establish? Are there bilateral contract structures or are there central H2 vendors that bundle capacities on the generation side and distribute them among the customers?

- How will energy surpluses be handled in the market? Who is responsible for curtailing and balancing energy quantities?

- High H2 purities (5.0, or ≥999%) at withdrawal cannot be guaranteed in a converted pipeline. How can an efficient mechanism be found here?

- In the heating or industrial sector, there are different regulatory frameworks than in transportation (THG-Quote credit systems). How can the different incentives be reconciled in one market?

Modularly constructed electrolysis units

Through joint planning and close coordination in the consortium, reliable and functioning structures will be created that reduce the risk for all project undertakers and enables a simultaneous ramp up of H2 supply and demand.

The H2 producer ensures economic H2 production in the initial phase through the intelligent combination of energy from their own wind and PV ground-mounted systems that supply the electrolyzers with CO2-free energy. Having their own RE plants guarantees that the H2 producers have available a long-term, plannable supply of electricity with fixed prices.

A modular design and the flexible plant structure composed of several containerized MW electrolysis units will make adapting to the physical and legal requirements of hydrogen for different supply strings in the TH2ECO project at an electrolysis site possible. In this way, from the start, filling a high-pressure trailer with 5.0 purity green hydrogen as defined in EU directive REDII and eventually feeding CO2-free green hydrogen at 30 bar into the H2 grid can occur. Synergies of H2 demand and different revenue streams are thus used in a way that enables efficient cash intakes in the different areas of use.

H2Eco Award for TH2ECO

During Hannover Messe, TH2ECO and namely Green Wind Innovation was distinguished with the H2Eco Award – a distinction by the DWV (German hydrogen and fuel cell association) and Deutsche Messe for companies whose projects make an outstanding contribution to the ramp-up of the hydrogen economy. In the project TH2ECO, where it is a consortium member, Green Wind Innovation is responsible for the set-up of a modular 10-MW electrolysis plant. According to the assessment by the jury of notable figures, the project distinguishes itself through a special system technological, national economic contribution to climate protection and CO2 reduction.

TH2ECO MOBILITY is a HyPerformer

In the area of transportation, the planned refueling station in GVZ Erfurt will make higher revenue potentials with hydrogen possible. Recently, the subproject TH2ECO MOBILITY, led by consultancy EurA Innovationsberatung, was named a HyPerformer 2023 by the German transport ministry. To realize the development of an H2 mobility hub in the GVZ, 15 million euros of federal funding has been allocated.

In the area of industry, with a suitably coordinated H2 product, a CO2-free energy source will be created, which can also be used as a chemical starting material. For the centralized heating of Stadtwerke Erfurt, a CO2-free heating product will be available in the market.

Security of supply increasing

With TH2ECO, an H2 ecosystem is being created that uses the potentials of cheap renewable energies from wind and PV plants and incorporates the fluctuation of energy sources through the buffer and storage capabilities of an H2 pipeline. In this way, the constant demand from industry, daily fluctuating demand from transportation, and seasonally fluctuating demand in the heating sector can be brought together with renewable energy from regional sources.

In the combined heat-and-power station of Stadtwerke Erfurt, hydrogen is to be used to generate grid heat. About 40 percent of the residents of Erfurt can proportionately and directly benefit from this. Furthermore, by blending H2 in sections of the existing natural gas grid, households in these microgrids will be supplied with green hydrogen.

In the medium term, one of the largest economic centers of Thüringen, that is industrial park Erfurter Kreuz, as well as the rail transport systems will be incorporated. The planned connection starting 2030 to the German and European Hydrogen Backbone (EHB) will support the commercial prospects beyond the borders of Thüringen and Germany in the long term. In this way, the commerce of locations Germany and particularly Thüringen will be strengthened by the TH2ECO project.

Project development of the electrolysis station

Could you illustrate what the project development of the electrolyzers was like?

Fromm: During the realization of the electrolysis plant from Green Wind, the local community was actively involved early on through a presentation for the Bürgermeister in the town hall, in a building committee and in town council meetings. Like with the installation of wind energy in Thüringen, we are convinced that a fair involvement of the community in the projects is necessary. Additionally, consultation with critical stakeholders like regional water providers was done in order to ensure an environmentally considerate water supply.

What advantages are there at the electrolysis location?

Our approach is to use the complete feed-in energy of the electrolysis plant. Therefore, in addition to the generation of green hydrogen, the decoupling of local heat on site at the electrolysis plant is planned. A helpful potential, since its operation generates low-cost waste heat that – when locally used – is a helpful building block in the clean heating transition of the community, for example as part of a low-temperature heating grid.

Are there advantages on site beyond the waste heat?

Yes, definitely: We envisage that there will be an opportunity to visit at the electrolysis site, so it will become a place for knowledge expansion and learning. By being present locally, we want to develop a practical example that can be experienced and that gives the important topics of energy transition and sector coupling the visibility they deserve.

Author: Kilian Fromm, Green Wind Innovation, Berlin