by Sven Jösting | Jan 15, 2024 | Europe, News, Stock market, worldwide

The numbers for the third quarter and the outlook promise a very exciting future for Hyzon Motors and its 200‑kW FC modules for trucks. Series production will begin in the second half of 2024. The activities will be concentrated at one location in the USA. Hyzon with its subsidiary is withdrawing from Europe. That is the right step, since a young company should concentrate on the market that is most important to the company, in order to use the limited capital resources in a targeted way.

Hyzon, however, is still looking for a fulfillment partner in Europe who can independently bring to use the company’s FC stacks, comparable to the partnership with Fontaine Modification in the USA or one like Quantron with Ballard Power. Hyzon is focusing on the USA and Australia/New Zealand, where a hydrogen-powered waste collection truck was recently delivered to Remondis. The FC modules are produced in the USA, which makes sense given the subsidies.

Advertisements

Hyzon will also benefit from the development of the H2 hubs, because the MACH2 project in the Midwest lies in the vicinity of its own production facility and belong to the projects of the DOE subsidized as part of the seven billion-dollar hydrogen hub program (awards of one billion dollars for each hub).

At the same time, Hyzon announced that they have agreed with the SEC to a payment of 25 million USD, payable in three installments over the next few years. This concludes this unspeakable issue, which is based on the misconduct of the former board of directors (accounting scandal). The cash burn per month can be massively reduced, and for ramp-up of module production only about five million USD is required. At the end of the third quarter are still 137.8 million USD in the bank, at a capital requirement of 10 million USD per month.

With the parent company and majority shareholder Horizon from Singapore, the IP license agreement was able to be extended until 2030 and could also be extended to other activities: So Hyzon is also planning to introduce new 300‑kW FC single stacks into the stationary energy supply of data centers and hospitals. Ballard Power and Bloom Energy are already active in this area.

Parker Meeks, CEO of Hyzon, responded to a question about why his company was focusing exclusively on fuel cells and not electric vehicles: „The experience with battery-electric trucks for many has been one in which the usable range is not what they imagined, especially when going uphill, which is the case even in the Los Angeles Basin. If you know the area, if you’re going somewhere where there’s a long distance, you’ll probably have to drive up a hill. Fuel cell trucks do not lose power, and this is the crucial factor that makes them particularly suitable for heavy transport as opposed to transporting drinks.”

Summary: In the USA Hyzon is working on establishing and expanding capacities in order to ramp up production of the 200‑kW FC modules. The partnership with Fontaine Modification suggests that a large sales market is emerging here, as Fontaine rebuilds trucks or retrofits vehicles and Hyzon as a technology partner in this comes perfectly into use with its FC modules. In this context, we can also well imagine that Fontaine through parent company Marmon Holdings has a direct stake in Hyzon. There will surely be capital measures (new issue of shares), and the entry of a strategic partner would be the ideal way to achieve this.

A highly speculative, very interesting investment. Hyzon is suitable as an admixture to Ballard Power and Nikola Motors, as these three companies can be jointly assigned to the area of fuel cells in commercial vehicles.

Disclaimer

Each investor must always be aware of their own risk when investing in shares and should consider a sensible risk diversification. The FC companies and shares mentioned here are small and mid cap, i.e. they are not standard stocks and their volatility is also much higher. This report is not meant to be viewed as purchase recommendations, and the author holds no liability for your actions. All information is based on publicly available sources and, as far as assessment is concerned, represents exclusively the personal opinion of the author, who focuses on medium- and long-term valuation and not on short-term profit. The author may be in possession of the shares presented here.

by Sven Jösting | Jan 15, 2024 | Fuel cells, hydrogen development, international, News, Stock market, USA

Here, I am cautious. The company, in my opinion, does not yet offer any convincing prospects, expressed in terms of expected growth, orders and sales through the use of its technology, which was also supported by the share price drop to 1 USD. From this very low level, the price has now turned around, driven by the news. It looks as if a gradual rise in the share price is now imminent. FuelCell Energy reports a number of projects in Africa, the USA and Canada. Nigeria for example, plans to generate at least 30 percent of its energy from renewable sources by 2030 (MoU with Oando Clean Energy).

FuelCell Energy speaks of projects, but so far without naming order values; however, it is clear that demand for FC technologies such as solid oxide fuel cells (SOFC) is increasing. In Canada, a project with FuelCell Energy as technology partner was nominated for the Innovation Fund Award. Together with the companies Kinetrics and Bruce Power, the energy production of Ontario Power is to be expanded by hydrogen. And FuelCell Energy is about CO2-free hydrogen in commercial vehicles and about using electricity from nuclear power plants for hydrogen production (surplus electricity). Although this is only a pilot project, orders for high-temperature electrolyzers from FuelCell Energy are expected in the future.

Advertisements

Summary: The company has a healthy balance sheet structure and sufficient equity for financing. Unfortunately, FuelCell Energy does not yet have a long-term strategy that we can understand as to how FC technology and IP are to be used profitably. Cooperations such as that with ExxonMobil and IBM in the field of carbon capture sound very exciting, but how is money to be earned with such? The share will go its way, especially as support programs (Inflation Reduction Act) and the need for safe, clean energy form the basis for this. An own electricity portfolio (own plants, energy sales via PPA) will form the basis of the company’s earnings in the long term. A perfect FC/H2 share for traders.

Disclaimer

Each investor must always be aware of their own risk when investing in shares and should consider a sensible risk diversification. The FC companies and shares mentioned here are small and mid cap, i.e. they are not standard stocks and their volatility is also much higher. This report is not meant to be viewed as purchase recommendations, and the author holds no liability for your actions. All information is based on publicly available sources and, as far as assessment is concerned, represents exclusively the personal opinion of the author, who focuses on medium- and long-term valuation and not on short-term profit. The author may be in possession of the shares presented here.

by Hydrogeit | Dec 12, 2023 | Europe, Germany, News

Effective and efficient cleaning of metal bipolar plates

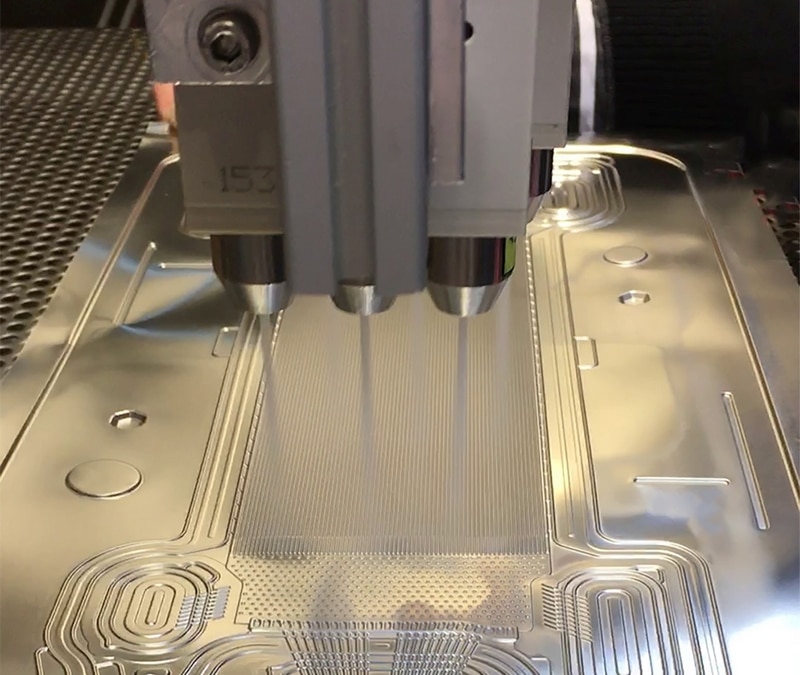

Low weight and volume, good cold-start capability and relatively inexpensive series production are all benefits associated with metal bipolar plates. These key elements in fuel cell stacks are responsible for handling the essential tasks of supplying media, creating an electrical connection and cooling. Their ability to perform these well depends on factors such as the cleanliness of both the material and the joined plate. Ecoclean has trialed a variety of processes to find the most effective and economical method of cleaning.

Advertisements

Fuel cells are among the key technologies for enabling the electrification of vehicle propulsion systems and also have a major part to play in the energy transition as a stationary energy source. At the heart of a fuel cell system are the bipolar plates or BPPs that are connected to the stacks. BPPs consist of an anode and a cathode with a proton-conducting film sandwiched between them.

BPPs fulfill a variety of tasks: They physically and electrically connect the anode of a cell to the cathode of the neighboring cell. They are also responsible for conveying the reactant gases – hydrogen on the anode side and air on the cathode side. For this purpose, the plates are designed with flow fields on both sides whose form is crucial for the performance of the overall system. In addition, the BPPs control the release of electrical energy and the removal of water vapor. Another function they perform is the management of heat.

Plates can be manufactured from different materials: high-concentration graphite, graphite-polymer composites and metals. Metal bipolar plates offer advantages particularly when it comes to their use in automobiles. This is because they are low in weight and volume and have a good cold-start capability. What’s more, metal BPPs offer the potential for comparatively cost-effective series production which can be further improved through scaling.

Clean for quality and efficiency

The anode and cathode of metal BPPs are predominantly made from stainless steel alloy foils with a thickness of 0.1 mm to 0.2 mm. The material is usually rolled off a coil whose surfaces are contaminated during manufacturing by different rolling and drawing greases, oils, emulsions and other unknown impurities. In the next step, the anode and cathode foils are precisely reshaped in a mechanical or hydroforming process and the outer contours are cut, for instance, by punching or laser cutting.

Residual machining fluids (oils and/or emulsions) are also left on the plates following these processes. When the anode plate and cathode plate are subsequently joined, commonly in a laser welding process, this results in smoke residue and oxide being left behind. Finally, the bipolar plates are coated. A cleaning stage must be performed prior to the plates being coated, if not earlier, to ensure a homogeneous coating with good adhesion.

For tightly packed fuel cells, which are required to achieve a high output in minimal space, it is recommended that cleaning takes place before the joining stage. This prevents impurities becoming trapped between the anode and cathode which can become loose when the temperature rises during operation and block the microstructures of the flow fields. This would lead to a decrease in performance. At the same time, the intermediate cleaning stage will reduce the surface contamination from smoke residue and oxides during the laser welding process.

Choosing the right process

A key challenge in cleaning metal BPPs is the presence of usually invisible chemical film residue on the surfaces. This may be oils, greases, emulsions or other chemicals that are often of unknown composition. These unidentified contaminants require a cleaning solution that ensures they are removed reliably and appropriately. This is why German company Ecoclean has carried out experiments using laser and carbon dioxide snow-jet cleaning, wet-chemical solvent cleaning as well as steam-jet cleaning.

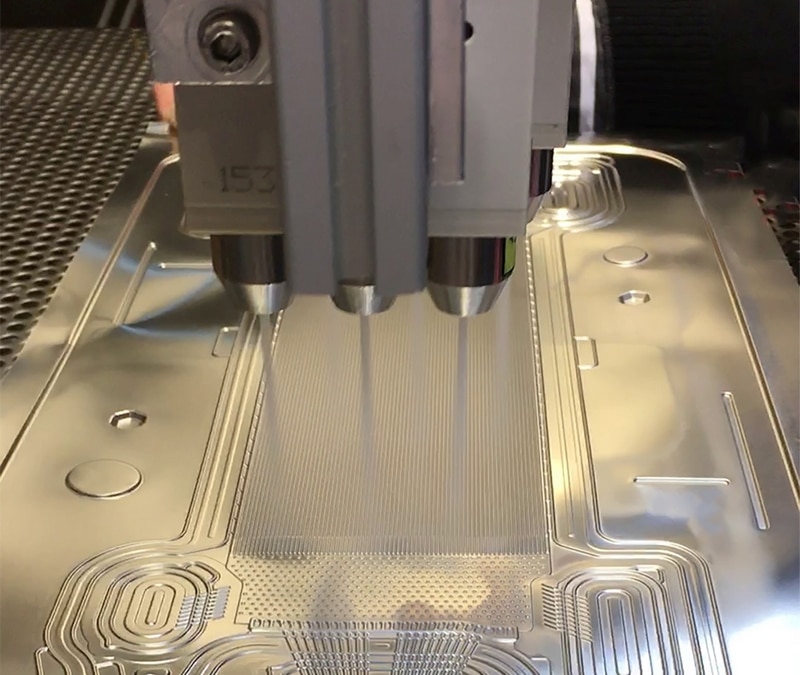

Fig. 2: Steam cleaning works due to a combination of steam, a precise quantity of fluid for the job, high-speed air flow and an adapted nozzle system

Both the laser and carbon dioxide snow-jet methods effectively removed smoke residue, oxide, chemical film contamination and particles from the welded seams of the joined bipolar plates with pin-point precision and within a matter of seconds. Good results were also recorded for both processes when cleaning whole BPP surfaces. Because the laser has to travel over the surface line by line, this option is time consuming. In the case of carbon dioxide snow-jet cleaning, the system can be fitted with an appropriate number of nozzles, thereby allowing for rapid treatment of the entire surface.

Wet-chemical cleaning with solvent using a flood method was able to successfully remove oils, greases and particles. However, it is not suitable for cleaning off emulsions, smoke residue and oxides. Wet-chemical immersion cleaning with water-based media is only possible to a limited degree due to the drying required and the considerable effort involved.

Good results were also achieved when using steam jets to clean chemical film and particulate contamination as well as smoke residue and oxides. For this process, the cleaning effect comes from a combination of steam, a precise quantity of fluid for the job, high-speed air flow and an adapted nozzle design. The cleaning procedure also takes just a few seconds.

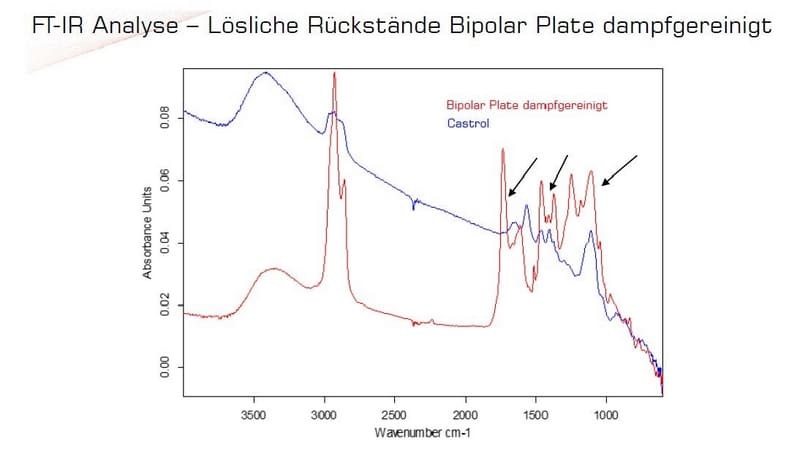

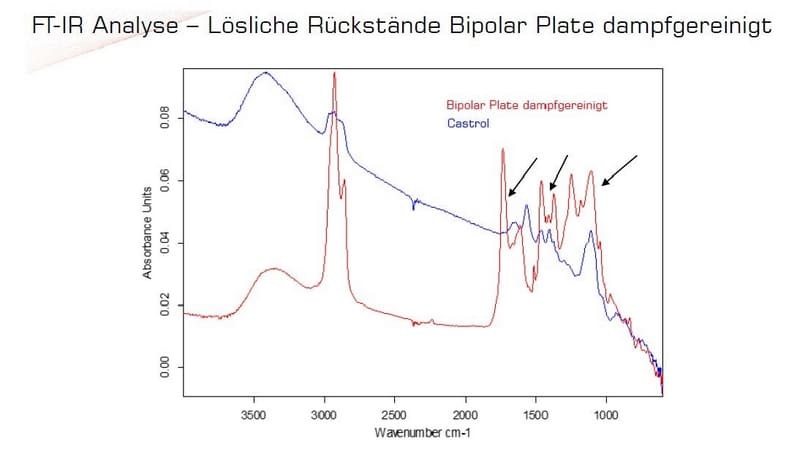

Fig. 3: Analysis from infrared spectroscopy showed that steam cleaning completely removed the residue of the reference contamination

Controlled cleaning validation

Cleaning results are verified using the surface tension through the measuring techniques of contact angle measurement and test inks, fluorescence measurement and infrared spectroscopy. The fluorescence measuring technique proved to be unsuitable due to the absence of fluorescent contaminants. In terms of the input measurements for surface tension, the bipolar plates produced very different contamination values which were significantly reduced after cleaning.

A general statement about whether the component has a sufficient level of cleanliness for the next processing step cannot be made. For this to be possible, it would be necessary to determine appropriate process-specific requirements. For infrared spectroscopy, all residue on the test pieces (coil sections and BPPs) was first removed to establish a reference cleanliness. After the surfaces of the test pieces were analyzed using infrared spectroscopy, the test pieces were contaminated with reference contamination before being cleaned and then reanalyzed. This analysis then showed that steam cleaning managed to reliably remove chemical film contamination.

The cleaning trials and tests outlined were carried out in Ecoclean’s test center in Monschau by experts in component cleaning and surface treatment using the methods described as well as other techniques.

Automated cleaning

For an efficient workflow, it is possible for cleaning to be integrated prior to joining and/or coating in production lines. Automation can be adapted and optimized to suit the specific requirements and conditions of each production line.

Ecoclean is part of the SBS Ecoclean Group which develops, produces and distributes cutting-edge equipment, systems and services for industrial component cleaning and surface treatment. Its solutions help companies around the world from the automotive and supply industries as well as the highly diversified industrial market to implement efficient and sustainable production processes. The group has an international presence with 12 sites in nine countries and employs more than 900 staff.

by Niels Hendrik Petersen | Dec 7, 2023 | Europe, News

Swedish port on the island Tjörn wants to be completely green

Plastic waste is a huge problem to the environment. One that is growing and growing with each passing day. On another hand, the global energy transition requires clean hydrogen in large quantities. So why not use the waste to generate the gas in a CO2-neutral way? Innovative technologies and projects show how this could be done. They are doing pioneering work and solving several problems all at once.

Advertisements

The municipality Tjörn, north of Göteborg on the west coast of Sweden, has decided: It wants local energy production free of fossil fuels. The technology of Boson Energy from Luxembourg is to help in this. It takes non-recyclable waste and transforms it into clean electricity and green methanol. Green methanol could help the chemical and plastic industry replace fossil fuels.

The bonus: Both the electricity and the fuel for the port are to be negative-carbon through this, because Boson Energy’s process enables both a capture as well as the storage of CO2. With this process, the only solid that remains is a kind of slag. This can, however, be used as an environmentally friendly filling material or further processed into climate-friendly insulation material.

The first phase of the project required an investment of 100 million euros – the total cost will amount to around 450 million euros. “The project in Wallhamn will enable us to demonstrate all aspects of our circular economy vision,” said Jan Grimbrandt, founder and CEO of Boson Energy. The Swede is a green pioneer. He was already co-founder of the company Mobotec Europe, which has upgraded coal-fired power plants for operation with 100 percent biomass. In 2008, Grimbrandt founded the company Boson Energy.

Use in the port and in greenhouses

The project on the island Tjörn is now to demonstrate how a changeover can be made for areas and applications in which decarbonization is likewise difficult: fuels for ships, the chemical industry, fertilizers and in greenhouses for local food production. “This project will be a model for the world,” Grimbrandt is certain. And not just for ports, but also for cities and islands confronted with energy access issues and want to get away from fossil fuels.

Fig. 2: Signing the memorandum of understanding – Torbjörn Wedebrand (CEO of Wallhamn AB) on the left and Jan Grimbrandt (CEO of Boson Energy SA)

Boson Energy has already signed an agreement with the startup Ecopromt. From the cooperation, a greenhouse for vegetable growing is to appear near the port. The concept developed by Ecopromt shall ensure a circular and space-efficient vegetable production in this – that doesn’t impact the environment. Putting the growing facility in the vicinity of the Boson Energy plant enables electricity, carbon dioxide and cooling to be directly supplied to the facility, which enables energy- and climate-efficient cultivation.

The Boson Energy plant is to generate 70,000 tonnes of green methanol produced from self-generated carbon dioxide and from hydrogen as well as supply an about 60,000-m2 autonomous greenhouse facility with electricity, green CO2, heat and cooling. Additionally, thermal energy will be supplied to port buildings. The water that is generated in the fuel cells is also recovered and used – in a closed cycle.

The municipality has, among other things, checked the suitable industrial sites in the areas identified in the ongoing detailed planning and design process. After all, it is benefitting from the fossil-free energy supply and sustainable jobs that will result.

One of the goals of the project is to make the transshipment port Wallhamn into the first negative-carbon ports in the world. The generation of local electricity means that all vehicles in the port will have clean charging and operation in the future. Shore power connections for ships that come in are also to be offered. Grimbrandt figures a total of 30 to 40 GWh of green electricity from hydrogen. This covers DC-DC charging of heavy-duty vessels, power for port operations and shore power connections as well as, with an energy management concept, smooth operation during load peaks.

Trash into green hydrogen

But not only Grimbrandt and Boson Energy are working to produce clean hydrogen from waste. With the technical solution of the company H2-Enterprises from New York, wastes such as plastic, sewage sludge and landfill contents are to be converted into clean hydrogen through incineration. H2-Enterprises uses an H2 thermolysis method that, at high temperatures in the absence of oxygen, converts plastics and carbonaceous waste into hydrogen and CO2.

It is a two-step process: First, steam reforming takes place, followed by the water-gas shift reaction and the separating out of H2 and CO2. At the end, the hydrogen can be further purified as needed. The captured CO2 can be used for commercial purposes or stored. Likewise, the clean H2 gas obtained from the process can be transported and stored as a liquid organic hydrogen carrier (LOHC). The green gas can be sold in this form to customers around the world – or further processed into synthetic fuels such as e-diesel or sustainable aviation fuel (SAF).

100 kg H2 from one tonne of waste

This solution almost sounds too good to be true. Because it contributes to global environmental protection from two points at once: by elimination of waste and by the production of green H2. Both are urgently needed. According to the International Energy Agency (IEA), the global demand for hydrogen in year 2030 could exceed 200 million tonnes in the desire to meet promised climate targets. In addition to reaching the sheer volume, however, the emissions-free hydrogen must also be offered at a competitive price.

On the other hand, the World Bank calculates that yearly around 2 billion tonnes of household waste accumulates that is not or only partially disposed of in an environment-friendly manner. This corresponds to about one third of the total discarded. Every minute, an amount of waste equal to the capacity of a garbage truck is dumped into the ocean. At this rate, by 2050, there will be more plastic than fish in the ocean. Already, from one tonne of waste, 100 kg of H2 can be recovered.

by Niels Hendrik Petersen | Dec 7, 2023 | Germany, News

Technology group Bosch is increasing its involvement in water treatment for green hydrogen. Alongside its work on reverse osmosis, Bosch is developing new plants in Renningen, Stuttgart-Feuerbach and Budweis that are especially robust and low in maintenance and are particularly suitable for remote areas and offshore locations.

These plants remove minerals from the water using thermal and electrochemical processes. It is claimed that this treatment process, which does not use any filter media, allows operators to relinquish the use of chemicals entirely. The first external pilot projects are due to start this year. Market launch for the plants is scheduled for 2024.

Advertisements

Water treatment is the essential first link in the hydrogen value chain since electrolyzers generally need highly purified water. The new technology will enable far-flung areas to have access to economical and environmentally sound water treatment, explained Stefan Hartung, board chairman at Bosch.